Customer service staff online 7/24

Best Quality Compressor For Sandblasting - Support customized screw air compressors energy saving – OPPAIR

Best Quality Compressor For Sandblasting - Support customized screw air compressors energy saving – OPPAIR Detail:

Permanent Magnet Frequency Conversion Series

| Model | OPP-10PV | OPP-15PV | OPP-20PV | OPP-30PV | OPP-40PV | OPP-50PV | OPP-60PV | OPP-75PV | |

| Power (kw) | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | |

| Horsepower (hp) | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 75 | |

| Air displacement/ Working pressure (M³/Min. / bar) |

1.2 / 7 | 1.6 / 7 | 2.5 / 7 | 3.8 / 7 | 5.3 / 7 | 6.8 / 7 | 7.4 / 7 | 10.0 / 7 | |

| 1.1 / 8 | 1.5/8 | 2.3/8 | 3.6 / 8 | 5.0 / 8 | 6.2 / 8 | 7.0 / 8 | 9.2 / 8 | ||

| 0.9 / 10 | 1.3 / 10 | 2.1 / 10 | 3.2 / 10 | 4.5 / 10 | 5.6 / 10 | 6.2 / 10 | 8.5 / 10 | ||

| 0.8 / 12 | 1.1 / 12 | 1.9 / 12 | 2.7 / 12 | 4.0 / 12 | 5.0 / 12 | 5.6 / 12 | 7.6 / 12 | ||

| Air out let diameter |

DN20 | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | DN50 | |

| Lubricating oil volume (L) | 10 | 16 | 16 | 18 | 30 | 30 | 30 | 65 | |

| Noise level dB(A) | 60±2 | 62±2 | 62±2 | 64±2 | 66±2 | 66±2 | 66±2 | 68±2 | |

| Driven method | Direct driven | ||||||||

| Type | PM VSD | ||||||||

| Start method | Variable frequency start | ||||||||

| Length (mm) | 950 | 1150 | 1150 | 1350 | 1500 | 1500 | 1500 | 1900 | |

| Width (mm) | 670 | 820 | 820 | 920 | 1020 | 1020 | 1020 | 1260 | |

| Height (mm) | 1030 | 1130 | 1130 | 1230 | 1310 | 1310 | 1310 | 1600 | |

| Weight (kg) | 250 | 400 | 400 | 550 | 700 | 750 | 800 | 1750 | |

| Model | OPP-100PV | OPP-125F | OPP-150PV | OPP-175PV | OPP-200PV | OPP-275PV | OPP-350PV | |

| Power (kw) | 75.0 | 90 | 110 | 132 | 160 | 200 | 250 | |

| Horsepower (hp) | 100 | 125 | 150 | 175 | 200 | 275 | 350 | |

| Air displacement/ Working pressure (M³/Min. / bar) |

13.4 / 7 | 16.2 / 7 | 21.0 / 7 | 24.5 / 7 | 32.4 / 7 | 38.2 / 7 | 45.5 / 7 | |

| 12.6 / 8 | 15.0 / 8 | 19.8 / 8 | 23.2 / 8 | 30.2 / 8 | 36.9 / 8 | 43 / 8 | ||

| 11.2 / 10 | 13.8 / 10 | 17.4 / 10 | 20.5 / 10 | 26.9 / 10 | 33/ / 10 | 38.9 / 10 | ||

| 10.0 / 12 | 12.3 / 12 | 14.8 / 12 | 17.4 / 12 | 23 / 12 | 28.5 / 12 | 36 / 12 | ||

| Air out let diameter |

DN50 | DN50 | DN65 | DN65 | DN75 | DN90 | DN90 | |

| Lubricating oil volume (L) | 65 | 72 | 90 | 90 | 110 | 130 | 150 | |

| Noise level dB(A) | 68±2 | 70±2 | 70±2 | 70±2 | 75±2 | 85±2 | 85±2 | |

| Driven method | Direct driven | |||||||

| Type | PM VSD | |||||||

| Start method | Variable frequency start | |||||||

| Length (mm) | 1900 | 2450 | 2450 | 2450 | 2760 | 2760 | 2760 | |

| Width (mm) | 1260 | 1660 | 1660 | 1660 | 1800 | 1800 | 1800 | |

| Height (mm) | 1600 | 1700 | 1700 | 1700 | 2100 | 2100 | 2100 | |

| Weight (kg) | 1850 | 1950 | 2200 | 2500 | 2800 | 3100 | 3500 | |

PM VSD air compressor features

1. Fast response to load

The load reaction action is very fast, the traditional screw machine will affect the reaction speed with the change of processing time during the operation, but this new frequency conversion screw machine will not;

2.Low motor friction

In the structural design of the body, there is no bearing, which effectively avoids the friction between the bearing and the rotor, and there is no need to do too much maintenance on the motor during daily use;

3.High transmission efficiency

This variable frequency permanent magnet screw machine has undergone a great change in transmission, and adopts the direct transmission mode to reduce the energy loss during the transmission process, especially when the main engine and the motor are connected together;

The frequency conversion permanent magnet screw machine has fast response speed, low motor friction, high transmission efficiency, and high use value of the body, especially suitable for large factories.

Product description

SMART CONTROLLER

1. Adopts PLC multilanguage control system, beautiful and intuitive interface, easy to operate function, operators can quickly and easily adjust the compressor.

2. 14 protection functions such as overload protection, short circuit protection, reverse protection, low temperature protection, high voltage protection, etc. to fully protect the unit.

3. The advanced microcomputer control drive system realizes itelligent control, air volume variable speed control, automatic adjustment of load start and soft start. Inelligent dynamic control, dynamic display of the working status of each component of the compressor, visual pressure, temperature, current working curve, etc.

4. Large memory and equipped with printer interface; It can use computer remote monitoring or multiple linkage control between air compressors.

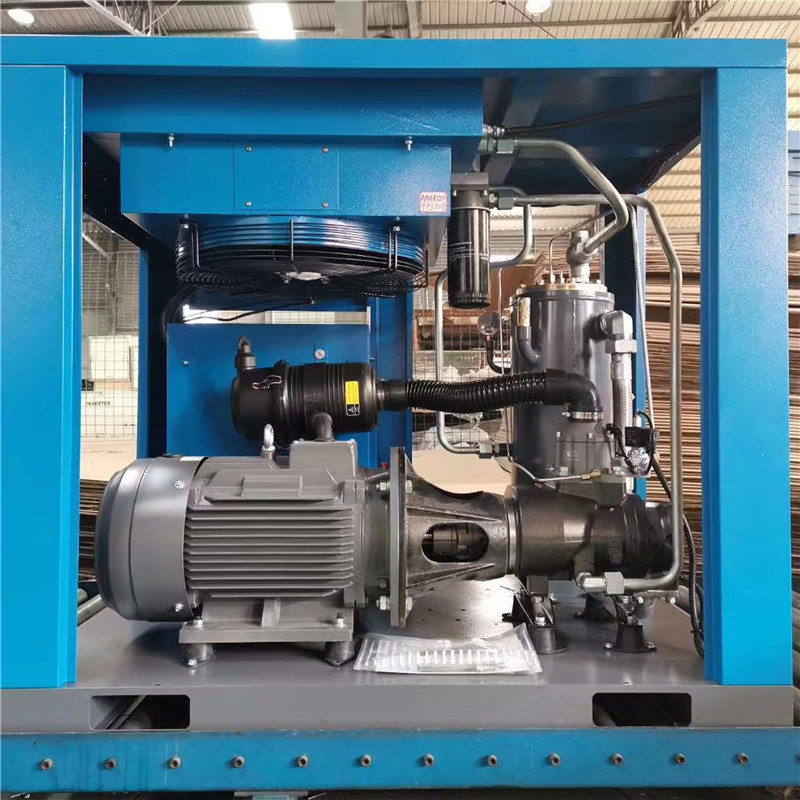

MOTOR

1. The motor uses high-performance motors of well-known brands. Permanent magnet synchronous motors (PM motors) use high-performance NdFeB permanentmagnets which will not lose magnetism under 200. and its service life reaches as long as 15 years.

2. The stator coil uses the frequency converter special halo proof enameled wire, theinsulation is outstanding and the service life is longer.

3. The motor has the function of temperature protection. It also has a wide range of motor speed regulation, high precision and wide range of volume regulation. The reliability is significantly improved with small size, low noise and large excess current.

4. Protection grade IP55, insulation grade F, efectively protects the motor and increases the serice life of the motor, the eficiency is 5% 7% higher than similar products.

INTAKE VALVE

1. Intake valve is the core component to control the air intake of the air compressor.

2. Adopting the world famous brand air intake valve, it can automatically adjust theair volume by 0-100% according to the requirement of the system air quantity. It promises small pressure loss, stable action and long life consequently reduced operating costs.

Product details

Factory Tour

Product detail pictures:

Related Product Guide:

Being supported by an state-of-the-art and skilled IT team, we could supply technical support on pre-sales & after-sales service for Best Quality Compressor For Sandblasting - Support customized screw air compressors energy saving – OPPAIR , The product will supply to all over the world, such as: Turin, Barcelona, Tunisia, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Shandong OPPAIR Machinery Manufacturing Co.,Ld base in Linyi Shandong, anAAA-level enterprise with high-quality service and integrity in China.

OPPAIR as one of the world’s largest air compressor system suppliers, currently developing the following products: Fixed-speed Air Compressors, Permanent Magnet VariableFrequency Air Compressors, Permanent Magnet Variable Frequency Two-stage Air Compressors, 4-IN-1 Air Compressors (lntegrated Air Compressor for Laser Cutting Machine)Supercharger, Freeze Air Dryer, Adsorption Dryer, Air Storage Tank and related accessories.

OPPAIR air compressor products are deeply trusted by customers.

The company has always operated in good faith in the direction of customer service first, integrity first, and quality first. We hope you will join the OPPAIR family and welcome you.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

Top