Customer service staff online 7/24

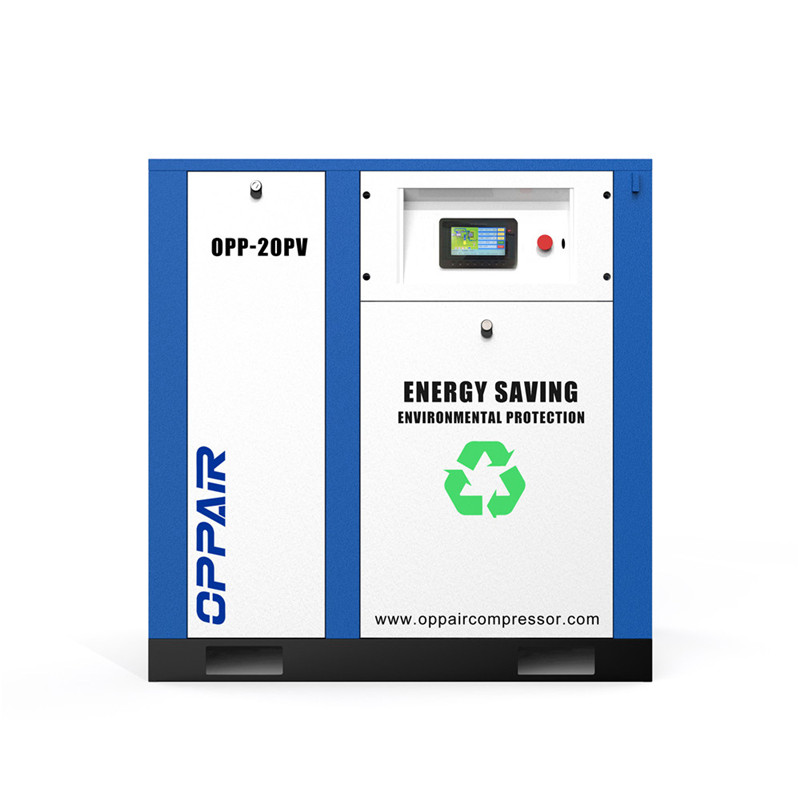

Good Quality Screw Air Compressor - Factory customized industrial equipment 300L 600L 1000L high quality – OPPAIR

Good Quality Screw Air Compressor - Factory customized industrial equipment 300L 600L 1000L high quality – OPPAIR Detail:

Product specification

| Model | OAT-300/8 | OAT-300/10 | OAT-300/13 | OAT-600/8 | OAT-600/10 | OAT-600/13 |

| Capacity (L) | 300L | 300L | 300L | 600L | 600L | 600L |

| Working pressure (bar) | 8 | 10 | 13 | 8 | 10 | 13 |

| Height (mm) | 1610 | 1610 | 1610 | 1905 | 1905 | 1905 |

| Inner diameter (mm) | 550 | 550 | 550 | 700 | 700 | 700 |

| Weight (kg) | 75 | 81 | 110 | 120 | 140 | 160 |

| Model | OAT-1000/13 | OAT-1000/13 | OAT-1000/13 | OAT-2000/8 | OAT-2000/10 | OAT-2000/13 |

| Capacity (L) | 1000L | 1000L | 1000L | 2000L | 2000L | 2000L |

| Working pressure (bar) | 8 | 10 | 13 | 8 | 10 | 13 |

| Height (mm) | 2180 | 2180 | 2180 | 2860 | 2860 | 2860 |

| Inner diameter (mm) | 800 | 800 | 800 | 1000 | 1000 | 1000 |

| Weight (kg) | 165 | 212 | 230 | 370 | 390 | 465 |

| Model | OAT-2000/8 | OAT-2000/10 | OAT-2000/13 | OAT-5000/13 | OAT-5000/13 | OAT-5000/13 |

| Capacity (L) | 3000L | 3000L | 3000L | 5000L | 5000L | 5000L |

| Working pressure (bar) | 8 | 10 | 13 | 8 | 10 | 13 |

| Height (mm) | 3020 | 3020 | 3020 | 3200 | 3200 | 3200 |

| Inner diameter (mm) | 1300 | 1300 | 1300 | 1600 | 1600 | 1600 |

| Weight (kg) | 510 | 703 | 850 | 890 | 1005 | 1021 |

Product description

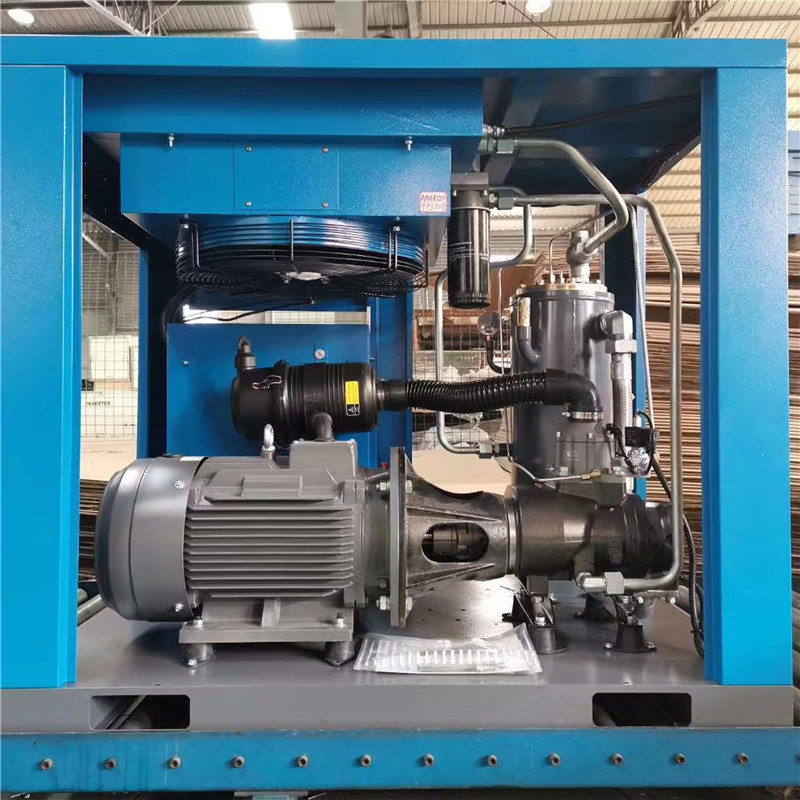

AIR END

1. Adopts the intermational top-level third-generation asymmetric wire twin-screw air end, adheres to the exquisite manufacturing process, adopts the peak high eficiency low pressure, high-fficiency tooth shape and the axial air inlet design.

2. Optimized flow channel design, with a large rotor, low speed and high eficiency. Increased energy eficiency by 5% -15% compared to the second generation.

3. Uses Swedish SKF heavy-duty bearings, doubl-lip lip shaft seal, durable and reliable. The bearing design life is 80,000-100,000 hours and the air end design life is about 200,000 hours.

FAN

1. The fan uses a large fan design to effectively enhance the fan’s heat dissipation effect.The motor adopts a special intermnal design to adapt to harsh working conditions.

2. The fan motor adopts specal winding and high protection grade design to adapt to harsh working conditions.

3. The fan is controlld by the controller to realie the automatic start and stop function, which efctively maintains the normal working temperature of the air compressor lubricant.

HEAT EXHANGER

1. The heat exchanger uses high-quality raw materials and a unique intemal channel design, which increases the heat exchange area and can effectively dissipate heat for the air compressor.

2. The inner wall of the heat exchanger is treated with corrosion protection to increase the service life of the heat exchanger and increase the heat transfer effect.

3. The radiator has passed the strict factory test, and the quality is reliable, which efetively prevents the high temperature of the air compressor and increases the service life of the machine.

Product Details

Factory Tour

Product detail pictures:

Related Product Guide:

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We're hunting forward to your check out for joint development for Good Quality Screw Air Compressor - Factory customized industrial equipment 300L 600L 1000L high quality – OPPAIR , The product will supply to all over the world, such as: Bahrain, Czech republic, luzern, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

Shandong OPPAIR Machinery Manufacturing Co.,Ld base in Linyi Shandong, anAAA-level enterprise with high-quality service and integrity in China.

OPPAIR as one of the world’s largest air compressor system suppliers, currently developing the following products: Fixed-speed Air Compressors, Permanent Magnet VariableFrequency Air Compressors, Permanent Magnet Variable Frequency Two-stage Air Compressors, 4-IN-1 Air Compressors (lntegrated Air Compressor for Laser Cutting Machine)Supercharger, Freeze Air Dryer, Adsorption Dryer, Air Storage Tank and related accessories.

OPPAIR air compressor products are deeply trusted by customers.

The company has always operated in good faith in the direction of customer service first, integrity first, and quality first. We hope you will join the OPPAIR family and welcome you.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

Top