Customer service staff online 7/24

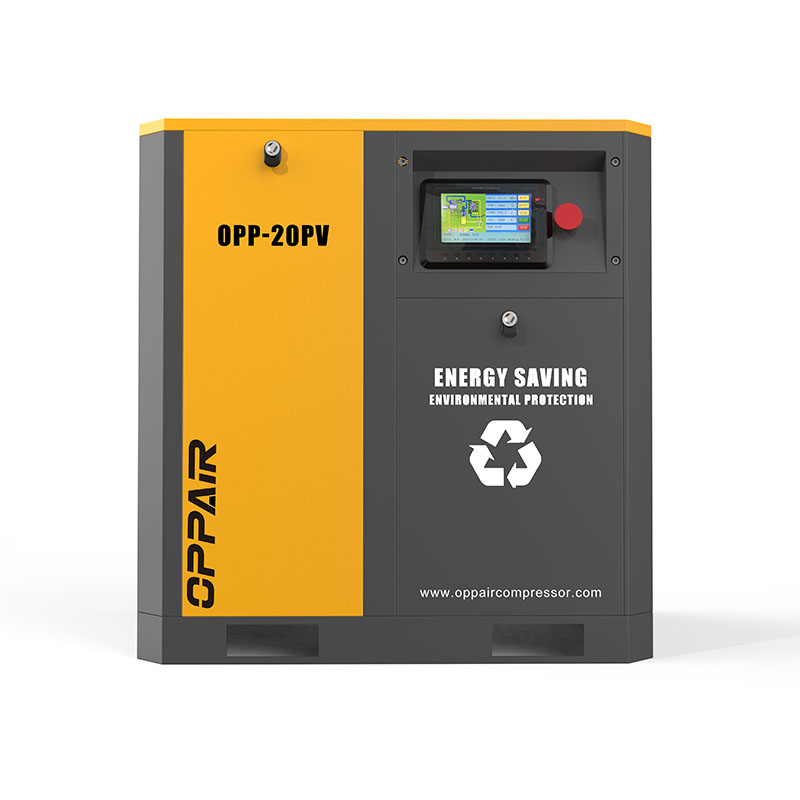

Hot Sale For Dry Screw Compressor - Diesel power screw air compressor – OPPAIR

Hot Sale For Dry Screw Compressor - Diesel power screw air compressor – OPPAIR Detail:

Product specification

| Model | |

| Model style | |

| Screw air compressor | Compression level |

| Exhaust pressure | |

| Volumetric flow | |

| Maximum towing speed (km/h) | |

| Main engine lubricating oil (L) | |

| Air supply valve size / quantity | |

| Maximum recommended working altitude | |

| Diesel engines | Rated power (kw) / speed (r / min). |

| brand name | |

| Number of cylinders | |

| Air inlet method | |

| Displacement (L) | |

| Engine lubricating oil quantity (L) | |

| Fuel tank capacity (L) | |

| Number of batteries | |

| Machine parameters | Long (mm) |

| Width (mm) | |

| High (mm) | |

| Weight (kg) | |

| Wheel size * quantity | |

| Noise level (sound level) db | |

| Exhaust emission standards | |

| OPM-194-13(F) | OPM-194-8 | Model | OPM-228-20 | OPM-228-22 | |

| Fixed Stype(No wheel) | Four wheels | Model style | Four wheels | Four wheels | |

| Single stage | Two-stage | Screw air compressor | Compression level | Two-stage | Two-stage |

| 13bar (189psi) | 8bar (116psi) | Exhaust pressure | 20bar (290psi) | 22bar (319psi) | |

| 17m3/min (595cfm) | 20m3/min (700cfm) | Volumetric flow | 22m3/min (770cfm) | 22m3/min (700cfm) | |

| 20 | 20 | Maximum towing speed (km/h) | 20 | 20 | |

| 120 | 120 | Main engine lubricating oil (L) | 100 | 100 | |

| G1 1/2″ *1 G1″ *1 | G1 1/2″ *1 G1″ *1 | Air supply valve size / quantity | G1″ *1 G2″ *1 | G1″ *1 G2″ *1 | |

| 2000 | 2000 | Maximum recommended working altitude | 2000 | 2000 | |

| 194/2200 | 194/2200 | Diesel engines | Rated power (kw) / speed (r / min). | 228/2200 | 228/2200 |

| Cummins | Cummins | brand name | YUCHAI | YUCHAI | |

| 6 | 6 | Number of cylinders | 6 | 6 | |

| Turbocharging & inter-air cooling | Turbocharging & inter-air cooling | Air inlet method | Turbocharging & inter-air cooling | Turbocharging & inter-air cooling | |

| 8.3 | 8.3 | Displacement (L) | 8.4 | 8.4 | |

| 22 | 22 | Engine lubricating oil quantity (L) | 24 | 24 | |

| 320 | 320 | Fuel tank capacity (L) | 430 | 430 | |

| 2 | 2 | Number of batteries | 2 | 2 | |

| 3500 | 3670 | Machine parameters | Long (mm) | 3670 | 3670 |

| 1800 | 1870 | Width (mm) | 1870 | 1870 | |

| 2400 | 2400 | High (mm) | 2350 | 2350 | |

| 3900 | 3900 | Weight (kg) | 4100 | 4100 | |

| 7.5-16-14RP*4 | 7.5-16-14RP*4 | Wheel size * quantity | 215/75R16*4 | 215/75R16*4 | |

| 82 ± 3 | 82 ± 3 | Noise level (sound level) db | 82 ± 3 | 82 ± 3 | |

| Non-road country three | Non-road country three | Exhaust emission standards | Non-road country three | Non-road country three | |

| OPM-242-17 | OPM-264-25(F) | Model | OPM-264-25 | OPM-264-23 | |

| Four wheels | Fixed Stype(No wheel) | Model style | Four wheels | Four wheels | |

| Two-stage | Two-stage | Screw air compressor | Compression level | Two-stage | Two-stage |

| 17bar (247psi) | 25bar (363psi) | Exhaust pressure | 25bar (363psi) | 23bar (334psi) | |

| 21m3/min (735cfm) | 28m3/min (980cfm) | Volumetric flow | 28m3/min (980cfm) | 29m3/min (1015cfm) | |

| 20 | 20 | Maximum towing speed (km/h) | 20 | 20 | |

| 120 | 120 | Main engine lubricating oil (L) | 120 | 120 | |

| G1 1/2″ *1 G1″ *1 | G1 1/2″ *1 G1″ *1 | Air supply valve size / quantity | G1 1/2″ *1 G1″ *1 | G1 1/2″ *1 G1″ *1 | |

| 2000 | 2000 | Maximum recommended working altitude | 2000 | 2000 | |

| 242/2200 | 264/2000 | Diesel engines | Rated power (kw) / speed (r / min). | 264/2000 | 264/2000 |

| Cummins | Cummins | brand name | Cummins | Cummins | |

| 6 | 6 | Number of cylinders | 6 | 6 | |

| Turbocharging & inter-air cooling | Turbocharging & inter-air cooling | Air inlet method | Turbocharging & inter-air cooling | Turbocharging & inter-air cooling | |

| 8.9 | 8.9 | Displacement (L) | 8.9 | 8.9 | |

| 26 | 28 | Engine lubricating oil quantity (L) | 28 | 28 | |

| 430 | 600 | Fuel tank capacity (L) | 600 | 600 | |

| 2 | 2 | Number of batteries | 2 | 2 | |

| 3670 | 3600 | Machine parameters | Long (mm) | 3800 | 3800 |

| 1870 | 1950 | Width (mm) | 2000 | 2000 | |

| 2350 | 2000 | High (mm) | 2250 | 2250 | |

| 4000 | 3800 | Weight (kg) | 4800 | 4800 | |

| 7.5-16-14RP*4 | // | Wheel size * quantity | // | // | |

| 82 ± 3 | 82 ± 3 | Noise level (sound level) db | 82 ± 3 | 82 ± 3 | |

| Non-road country three | Non-road country three | Exhaust emission standards | Non-road country three | Non-road country three | |

Product description

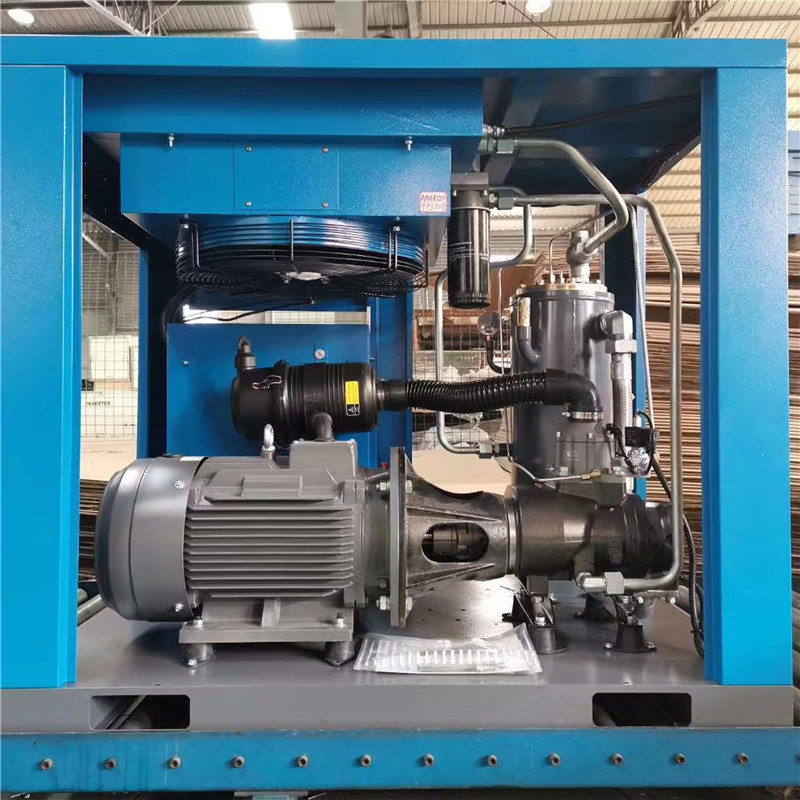

AIR END

1. Adopts the intermational top-level third-generation asymmetric wire twin-screw air end, adheres to the exquisite manufacturing process, adopts the peak high eficiency low pressure, high-fficiency tooth shape and the axial air inlet design.

2. Optimized flow channel design, with a large rotor, low speed and high eficiency. Increased energy eficiency by 5% -15% compared to the second generation.

3. Uses Swedish SKF heavy-duty bearings, doubl-lip lip shaft seal, durable and reliable. The bearing design life is 80,000-100,000 hours and the air end design life is about 200,000 hours.

MOTOR

1. The motor uses high-performance motors of well-known brands. Permanent magnet synchronous motors (PM motors) use high-performance NdFeB permanentmagnets which will not lose magnetism under 200. and its service life reaches as long as 15 years.

2. The stator coil uses the frequency converter special halo proof enameled wire, theinsulation is outstanding and the service life is longer.

3. The motor has the function of temperature protection. It also has a wide range of motor speed regulation, high precision and wide range of volume regulation. The reliability is significantly improved with small size, low noise and large excess current.

4. Protection grade IP55, insulation grade F, efectively protects the motor and increases the serice life of the motor, the eficiency is 5% 7% higher than similar products.

INTAKE VALVE

1. Intake valve is the core component to control the air intake of the air compressor.

2. Adopting the world famous brand air intake valve, it can automatically adjust theair volume by 0-100% according to the requirement of the system air quantity. It promises small pressure loss, stable action and long life consequently reduced operating costs.

HEAT EXHANGER

1. The heat exchanger uses high-quality raw materials and a unique intemal channel design, which increases the heat exchange area and can effectively dissipate heat for the air compressor.

2. The inner wall of the heat exchanger is treated with corrosion protection to increase the service life of the heat exchanger and increase the heat transfer effect.

3. The radiator has passed the strict factory test, and the quality is reliable, which efetively prevents the high temperature of the air compressor and increases the service life of the machine.

Product Details

Factory Tour

Product detail pictures:

Related Product Guide:

With our rich experience and considerate services, we have been recognized as a reliable supplier for many international buyers for Hot Sale For Dry Screw Compressor - Diesel power screw air compressor – OPPAIR , The product will supply to all over the world, such as: Slovak Republic, Colombia, Honduras, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

Shandong OPPAIR Machinery Manufacturing Co.,Ld base in Linyi Shandong, anAAA-level enterprise with high-quality service and integrity in China.

OPPAIR as one of the world’s largest air compressor system suppliers, currently developing the following products: Fixed-speed Air Compressors, Permanent Magnet VariableFrequency Air Compressors, Permanent Magnet Variable Frequency Two-stage Air Compressors, 4-IN-1 Air Compressors (lntegrated Air Compressor for Laser Cutting Machine)Supercharger, Freeze Air Dryer, Adsorption Dryer, Air Storage Tank and related accessories.

OPPAIR air compressor products are deeply trusted by customers.

The company has always operated in good faith in the direction of customer service first, integrity first, and quality first. We hope you will join the OPPAIR family and welcome you.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

Top