It is summer, and at this time, the high temperature faults of air compressors are frequent. This article summarizes various possible causes of high temperature.

1. The air compressor system is short of oil.

The oil level of the oil and gas barrel can be checked. After the shutdown and pressure relief, when the lubricating oil is at rest, the oil level should be slightly higher than the high oil level mark (the red line above). During the operation of the equipment, the oil level cannot be lower than the low oil level mark (red line below). If it is found that the oil quantity is insufficient or the oil level cannot be observed, stop the machine immediately and refuel.

2. The oil stop valve (oil cut-off valve) is not working properly.

The oil stop valve is generally a two-position two-position normally-closed solenoid valve, which is opened when starting and closed when stopping, so as to prevent the oil in the oil and gas barrel from continuing to spray into the machine head and spray out from the air inlet when the machine is stopped. If the component is not turned on during loading, the main engine will heat up rapidly due to lack of oil, and in severe cases, the screw assembly will be burned.

3. Oil filter problem.

A: If the oil filter is clogged and the bypass valve is not opened, the air compressor oil cannot reach the machine head, and the main engine will heat up rapidly due to lack of oil.

B: The oil filter is clogged and the flow rate becomes smaller. There is a situation that the air compressor is not completely taken away by the heat, and the temperature of the air compressor rises slowly to form a high temperature. Another situation is the high temperature of the air compressor after the air compressor is unloaded, because the internal oil pressure of the air compressor is high when the air compressor is loaded, the air compressor oil can pass through, and the air compressor oil pressure is low after the air compressor is unloaded. The oil filter of the air compressor is difficult, and the flow rate is too small, which causes the high temperature of the air compressor.

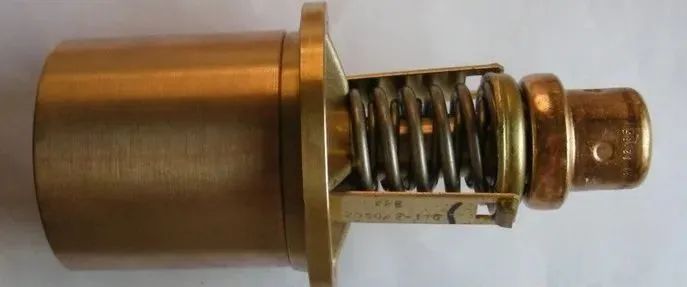

4. The thermal control valve (temperature control valve) is malfunctioning.

The thermal control valve is installed in front of the oil cooler, and its function is to maintain the exhaust temperature of the machine head above the pressure dew point.

Its working principle is that due to the low oil temperature when starting up, the thermal control valve branch circuit is opened, the main circuit is closed, and the lubricating oil is directly sprayed into the machine head without the cooler; when the temperature rises above 40°C, the thermal control valve is gradually closed, The oil flows through the cooler and the branch at the same time; when the temperature rises above 80°C, the valve is completely closed, and all the lubricating oil passes through the cooler and then enters the machine head to cool the lubricating oil to the greatest extent.

If the thermal control valve fails, the lubricating oil may directly enter the machine head without going through the cooler, so that the oil temperature cannot be lowered, resulting in overheating.

The main reason for its failure is that the coefficient of elasticity of the two heat-sensitive springs on the spool changes after fatigue, and cannot operate normally with temperature changes; the second is that the valve body is worn, the spool is stuck or the action is not in place and cannot be closed normally. Can be repaired or replaced as appropriate.

5. The fuel volume regulator is abnormal, and the fuel injection volume can be appropriately increased if necessary.

The fuel injection volume has been adjusted when the equipment leaves the factory, and it should not be changed under normal circumstances. This situation should be attributed to design problems.

6. If the engine oil exceeds the service time, the engine oil will deteriorate.

The fluidity of the engine oil becomes poor, and the heat exchange performance decreases. As a result, the heat from the head of the air compressor cannot be completely taken away, resulting in high temperature of the air compressor.

7. Check whether the oil cooler works normally.

For water-cooled models, you can check the temperature difference between the inlet and outlet pipes. Under normal circumstances, it should be 5-8°C. If it is lower than 5°C, scaling or blockage may occur, which will affect the heat exchange efficiency of the cooler and cause heat dissipation. Defective, at this time, the heat exchanger can be removed and cleaned.

8. Check whether the cooling water inlet temperature is too high, whether the water pressure and flow are normal, and check whether the ambient temperature is too high for the air-cooled model.

The inlet temperature of the cooling water should generally not exceed 35°C, and the flow rate should not be less than 90% of the specified flow rate when the water pressure is between 0.3 and 0.5MPA.

The ambient temperature should not be higher than 40°C. If the above requirements cannot be met, it can be solved by installing cooling towers, improving indoor ventilation, and increasing the space of the machine room. You can also check whether the cooling fan is working normally, and if there is any failure, it should be repaired or replaced.

Post time: Jun-02-2023