The chemical industry is an important pillar industry of the national economy, involving many complex process flows. In these processes, OPPAIR screw air compressors are widely used. For example, in polymerization reactions, the compressed air provided by rotary screw air compressors can help stir the reactants and improve reaction efficiency; in the material conveying process, compressed air can be used as a power source to drive the pneumatic conveying system; in addition, helical screw compressors also play an important role in equipment cleaning, product packaging and other links. As a key equipment for providing compressed air, the importance of air pressure machine is self-evident.

The application of OPPAIR screw air compressors in the chemical industry mainly includes the following aspects:

On-site nitrogen or oxygen production:

Many processes in chemical production require specific gases. Air pressure machine can be used for air separation. After air compression and separation, nitrogen and oxygen are obtained to provide raw materials for chemical synthesis, oxidation and other reactions.

Providing compressed air power source:

Screw air compressors are mainly used in chemical plants to provide compressed air as a power source for various equipment and processes. For example, pneumatic valves, pneumatic tools, and stirring of reactors all require compressed air to drive.

Material conveying and gas treatment:

Variable frequency screw air compressors can be used as a power source to drive pneumatic conveying systems during material conveying. In addition, hava kompresr are also used for gas processing, such as gas separation and gas conveying. For example, compressed air is used to separate mixed gases into nitrogen, helium, argon and other gases of standard purity.

Chemical reactions and synthesis:

In chemical reactions, compressed air provided by rotary screw air compressors can help stir reactants and improve reaction efficiency. For example, hydrogen reacts with crude oil after pressurization to promote the reorganization and light treatment of hydrocarbons.

Air purification:

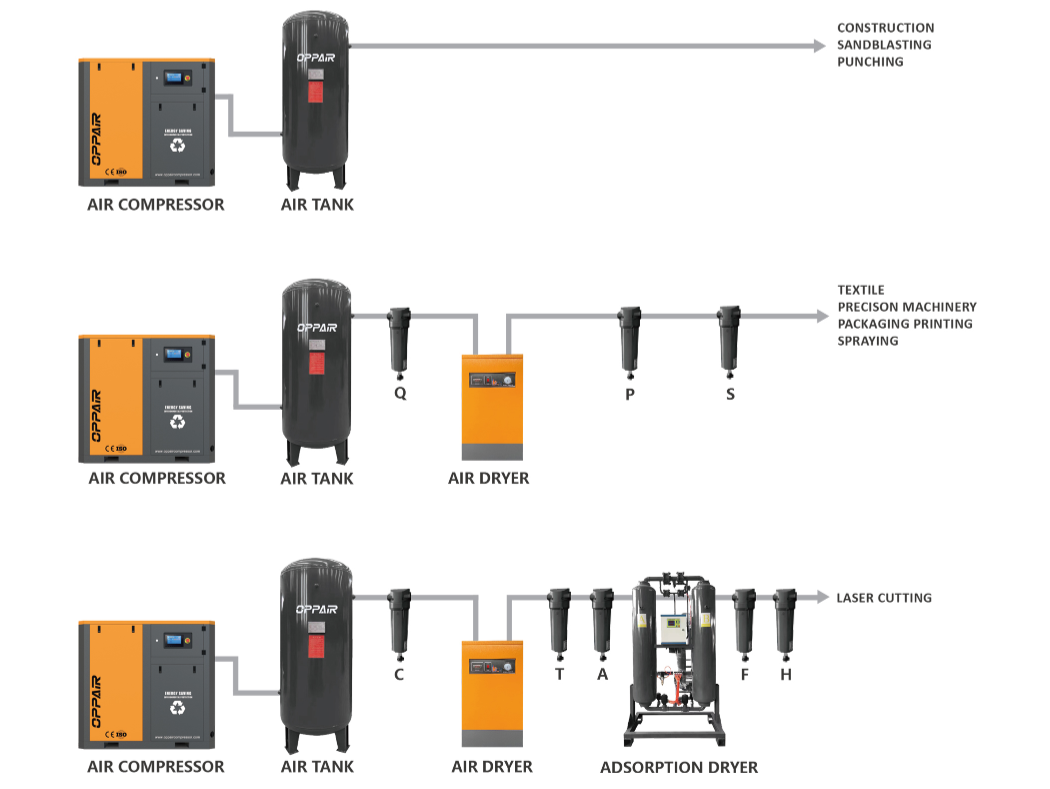

In the chemical production process, pure compressed air is required to prevent smoke, dust, moisture and other substances in the air from entering the production process. At this time, equipment such as filters and dryers are needed to purify the compressed air to ensure the quality of production.

Waste gas treatment:

In chemical plants, the waste gas generated needs to be treated to meet emission standards. At this time, compresor de tornillo are needed to provide compressed air to help the waste gas treatment process.

Safety and emergency systems:

OPPAIR screw air compressors play an important role in chemical safety. They can provide stable compressed air for the safety system to ensure that the safety device can be activated in time in an emergency. In addition, the stable operation of the air compressor can also reduce safety hazards in the production process.

Refrigeration and gas filling:

OPPAIR rotary screw air compressors are also used for artificial refrigeration and gas filling. Through the compression, cooling and expansion process, the gas can be liquefied and used in the refrigeration system. At the same time, screw kompresr are also used for gas filling and pipeline transportation.

Purge and cleaning:

Compressed air can be used for purging and cleaning of equipment and workshops.

Performance requirements of OPPAIR screw air compressors

Due to the particularity of the chemical industry, there are extremely high requirements for the performance of screw air compressors. Rotary screw air compressors need to have stable operating performance, high compression efficiency and low energy consumption. At the same time, for the corrosive environment of the chemical industry, air compressors also need to have good anti-corrosion performance and long life. In the chemical industry, the selection and configuration of air compressors are also crucial. Enterprises need to choose the appropriate air compressor model and configuration according to their own production needs and process flow. For example, for scenarios that require continuous air supply, an air compressor that can operate continuously and stably should be selected; for enterprises with high energy consumption requirements, energy-saving air compressors should be selected to reduce production costs.

The role of air compressors in chemical safety

The chemical industry has extremely high requirements for safety, and air compressors also play an important role in ensuring production safety. On the one hand, air compressors can provide stable compressed air for the safety system to ensure that safety devices can be activated in time in an emergency; on the other hand, the stable operation of air compressors can also reduce safety hazards in the production process.

In summary, the reason why air compressors are widely used in the chemical industry is mainly because they can provide a stable compressed air power source to meet the various needs of the chemical production process. At the same time, with the continuous advancement of science and technology and the increasing maturity of air compressor technology, its application in the chemical industry will be more extensive and in-depth.

OPPAIR is looking for global agents, welcome to contact us for inquiries: WhatsApp: +86 14768192555

Post time: Mar-20-2025