OPPAIR Screw air compressors are widely used in paper mills: they can be used for gas cleaning equipment, lifting equipment, anti-icing of water pools, pressing paper products, driven paper cutters, feeding paper through machines, removing waste paper, vacuum drying, etc.

1. Paper handling: During the paper making process, rotary screw air compressors provide stable compressed air for paper handling. For example, during the paper feeding process, key components such as paper separation nozzles and paper delivery nozzles rely on compressed air for precise movements to ensure that each piece of paper can be accurately fed into the printing process to avoid problems such as paper jams and poor paper feeding.

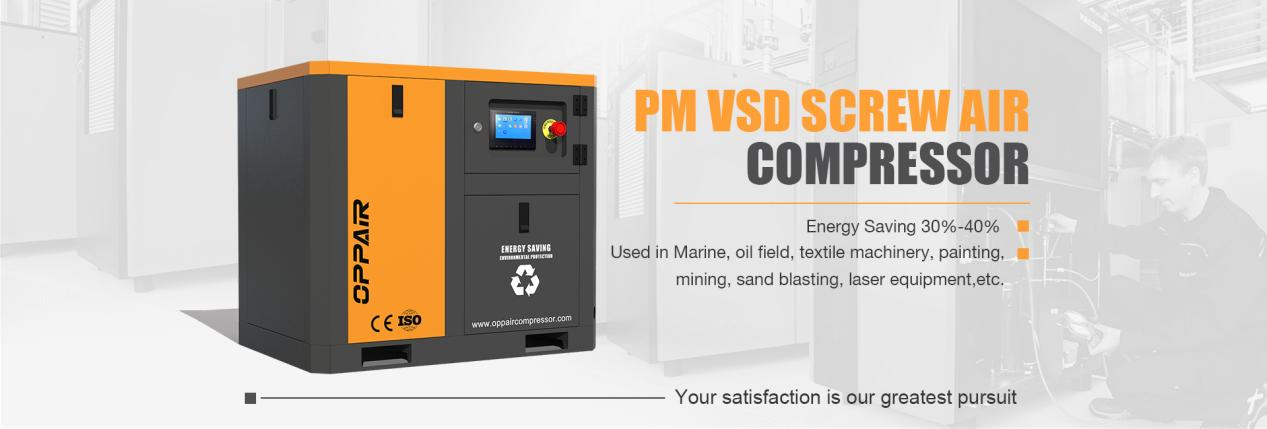

2. Paper feeding process: During the paper feeding process, vacuum adsorption and conveying technology requires a stable vacuum environment, which depends on the compressed air provided by the PM VSD screw air compressor. Stable compressed air ensures that the paper remains stable during the conveying process to avoid deviation, thereby improving the registration accuracy of printing.

3. Printing link: In the control of the ink roller and water roller of the printing press, the compressed air provided by the compresor de tornillo drives the ink roller and water roller to ensure the uniform transfer of ink and water during the printing process, and ensure the uniform color and stable quality of the printed product. In addition, the compresores de aire is also used for roller position control to ensure the precise fit between the impression roller and the printing plate, and to ensure the clarity of the printed product.

Modern permanent magnet variable frequency screw air compressors have the characteristics of high efficiency, energy saving and stable output. They use high-efficiency permanent magnet motors and imported bearings, meet the latest national standards, have high output efficiency and low energy consumption, and can meet the long-term stable supply needs of the papermaking industry.

OPPAIR permanent magnet variable frequency rotary screw air compressors have the following characteristics:

1. Adopting an efficient cooling system, the heat dissipation effect is high, which reduces the operating cost.

2. The compression host perfectly matches the permanent magnet variable frequency solution and has high reliability.

3. High-efficiency permanent magnet synchronous motor, the power factor is close to 100%, there is no excess loss, and the energy saving is better.

4. Variable frequency control technology is specially developed for permanent magnet motors, modular design, easy maintenance and expansion.

5. No motor bearing, the motor rotor is directly coaxial with the male rotor, eliminating motor failure.

6. Innovative cooling method, coated circuit board, significantly improve the stability and service life of the inverter.

7. Advanced microcomputer controller, large display, simple operation and easy to use.

8. Some components are equipped with rubber shock absorbers, which effectively reduces noise.

OPPAIR specializes in the production and sales of various pressure PM VSD and Fixed Speed screw air compressors and high-purity nitrogen generator.

Applied to: laser cutting, plastic bottle blowing, chemical industry, environmental protection, leak detection and pressure testing, shipbuilding, machinery, food and medical, electronics, textiles, building materials and other industries. Provide a variety of solutions for customers’ personalized needs.

OPPAIR is looking for global agents, welcome to contact us for inquiries: WhatsApp: +86 14768192555

Post time: Mar-21-2025