Screw air compressor

The OPPAIR rotary screw air compressor adopts a pre-packaged configuration. The screw air compressor only needs a single power connection and compressed air connection, and has a built-in cooling system, which greatly simplifies the installation work. The air pressure machine has consistently provided high-quality compressed air for all walks of life with its advantages of high performance, high efficiency, maintenance-free, and high reliability.

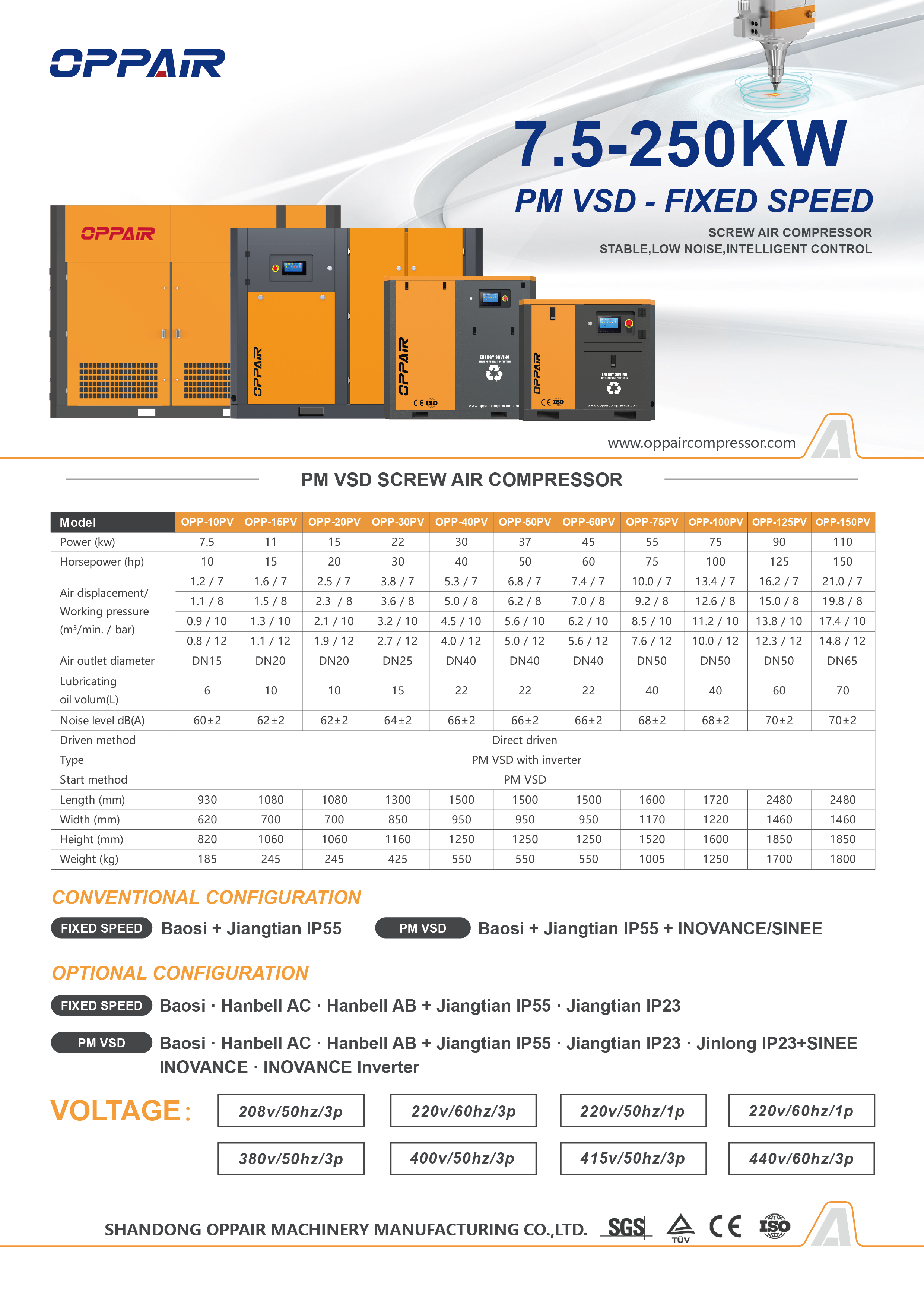

OPPAIR PM VSD screw air compressor main advantages

Its greatest advantages are excellent reliability, low vibration, low noise, easy operation, few wearing parts, and high operating efficiency.

The PM VSD rotary air compressor is a type of positive displacement compressor. The air is compressed by the volume change of the teeth of the yin and yang rotors that are parallel to each other and meshed in the casing. The rotor pair rotates in the casing that is precisely matched with it, so that the gas between the rotor teeth continuously produces periodic volume changes and is pushed from the suction side to the discharge side along the rotor axis, completing the three working processes of suction, compression, and exhaust.

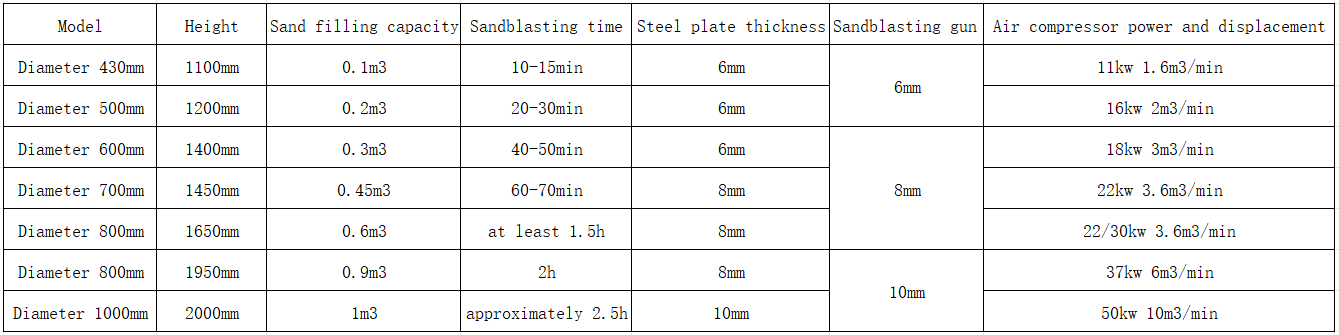

The relationship between screw air compressor and sandblasting machine

Sandblasting machine cannot be separated from air compressor. Denair compressor plays a pioneering role because its working principle is to use the compressed air generated by the helical screw compressor as the power source to form a high-speed jet beam to spray the abrasive at high speed onto the surface of the parts that need to be processed.

The application of OPPAIR screw air compressors in the sandblasting industry is mainly reflected in the following aspects:

Providing compressed air power: The variable frequency screw air compressor compresses air into high-pressure gas through its internal screw rotor system. These gases are then used to drive the spray gun in the sandblasting machine to form a high-speed spray beam to remove rust and impurities from the metal surface.

High efficiency and reliability: OPPAIR screw air compressors are known for their high efficiency and reliability. They can maintain stability during long-term operation and reduce maintenance requirements. This is very important for the sandblasting industry because the sandblasting process often needs to be carried out continuously.

Strong adaptability: Compresores de aire can adjust air flow and pressure according to different work requirements to ensure that sandblasting operations are carried out under the most optimized conditions, while also being able to handle high cleanliness standards.

Environmental protection and safety: Modern screw air compressors are usually equipped with efficient cooling systems and filtering equipment, which can effectively remove moisture and oil from compressed air, ensure the cleanliness and safety of the sandblasting process, and also meet environmental protection standards.

In short, the application of screw air compressor in the sandblasting industry is indispensable. It not only provides the necessary compressed air power, but also supports the efficiency and effectiveness of the sandblasting process through its high efficiency and reliability.

OPPAIR is looking for global agents, welcome to contact us for inquiries: WhatsApp: +86 14768192555

Post time: Mar-29-2025