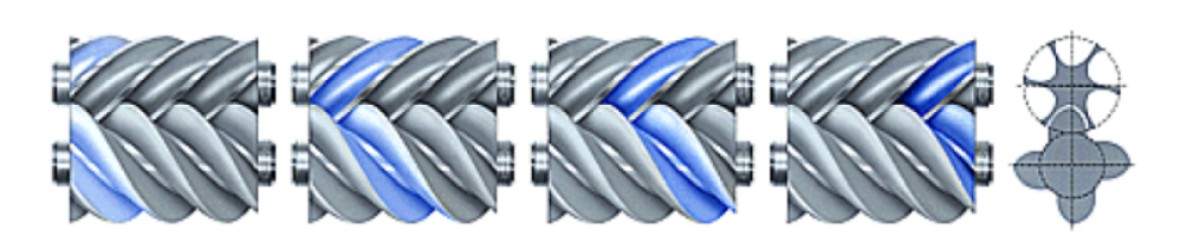

The oil injected rotary screw air compressor is a versatile industrial machinery that efficiently converts power into compressed air through a continuous rotary motion. Commonly known as a twin-screw compressor (figure 1), this type of compressor consists of two rotors, each featuring a set of helical lobes attached to a shaft.

One rotor is called the male rotor and the other rotor is the female rotor. The number of lobes on the male rotor, and the number of flutes on the female, will vary from one compressor manufacturer to another.

However, the female rotor will always have numerically more valleys (flutes) than the male rotor lobes for better efficiency. Male lobe acts like a continuous piston rolling down the female flute which acts like a cylinder trapping air and reducing space continuously.

With the rotation, the leading strip of the male lobe reaches the contour of the female groove and traps the air in the pocket previously formed. The air is moved down the female rotor groove and is compressed as the volume is reduced. When the male rotor lobe reaches the end of the groove, the trapped air is discharged from the air end. (figure 2)

Figure 2

This type of twin-screw compressors can be oil free or oil injected. In the case of the oil lubricated compressor oil is injected.

What are the benefits of rotary screw air compressors?

●Efficiency: They deliver a continuous and steady supply of compressed air, which is essential for applications that require a consistent flow of air. Their design minimizes fluctuations in pressure, leading to improved efficiency and reduced energy consumption.

●Continuous Operation: Rotary screw compressors can operate continuously without the need for frequent starts and stops, which can extend the lifespan of the compressor and improve overall system reliability.

●Adaptability: Rotary screw compressors can operate in both high and low conditions, even in areas where safety restricts other energy sources.

●Easy to maintain: Their minimal moving and contacting parts make maintaining compressors easy, reducing wear, extending service intervals, and simplifying routine checks and repairs.

●Low Noise Levels: These compressors are generally quieter than reciprocating compressors, making them suitable for environments where noise is a concern, such as indoor workplaces.

The following is a video of the air compressor in operation:

OPPAIR Rotary Screw Air Compressors Types

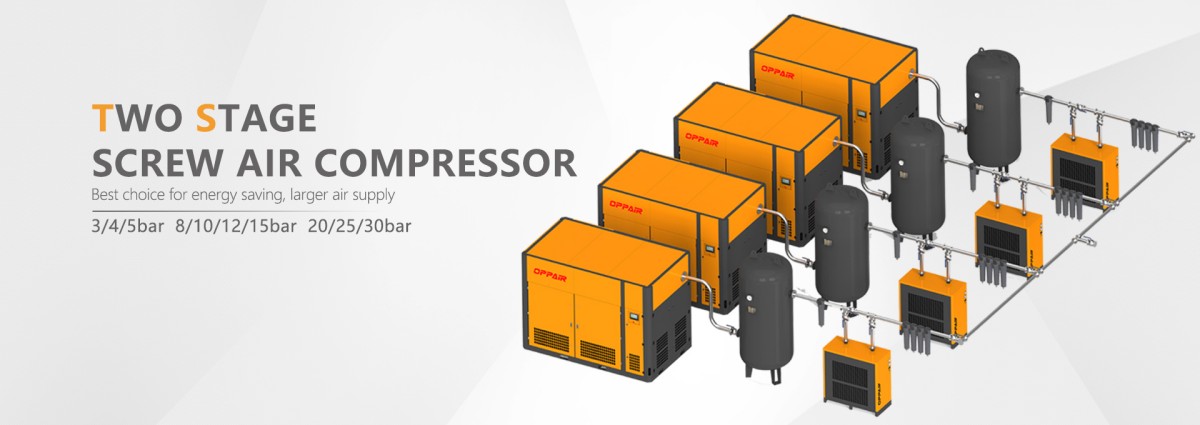

Two-stage Compressors

Two-stage lubricated rotaries compress air in two steps. Step or stage one takes atmospheric air and compresses it part way to the discharge pressure target. Step or stage two ingests the air at the inter-stage pressure and compresses it to the discharge pressure target. Compression in two stages improves efficiency, but adds cost and complexity given the additional rotors, iron and other component involved. Two-stage is generally offered in the higher HP ranges (100 to 500 HP) because the improved efficiencies result in larger dollar savings when air use is large.

Single-stage Compressors

Single stage versus two-stage, it is a relatively straightforward calculation to determine what the payback will be from the more efficient but more costly two-stage unit.

Remember that the energy cost of operating a compressor is the largest expense over time, so evaluation of a two-stage machine is certainly worth a look.

The following is the video for 90kw single stage compressor.

Lubricated

The lubricated rotary screw compressor has been the most popular technology for the majority of industrial plant air applications from 20 to 500 HP and from 80-175 PSIG. These compressors offer unmatched versatility and adaptability to various operational demands. Their efficient design ensures a continuous and reliable supply of compressed air, crucial for sustaining seamless production processes.

OPPAIR Rotary Screw Air Compressors, stand out as a superior choice in performance for a variety of reasons. Our compressors are rigorously tested to ensure accurate performance and quality, guaranteeing performance numbers are accurate, easy-to-understand. Reach out to our experts for assistance in selecting the ideal compressor series tailored to your specific needs!

Contact Us.Whatsapp:+86 14768192555. email: info@oppaircompressor.com

#High Efficiency Energy Saving Screw Compressor #Compresor De Aire #General Industrial Compressors #Low Noise Industrial High Efficiency 10HP 15HP 20HP 30HP 100HP Rotary compressor #Industrial Compressor Permanent Magnet #All in One Screw Air Compressor for 1000W-6000W Laser Cutting

Post time: Mar-11-2025