OPPAIR Rotary screw compressors are ideal for so many industries and applications. Unlike reciprocating compressors, rotary screw compressors are designed for continuous compressed air use and produce a consistent flow of air. Commercial and industrial businesses generally choose rotary compressors due to their reliability and maximum uptime, along with additional benefits such as a lower decibel output when compared to other compressor technologies.

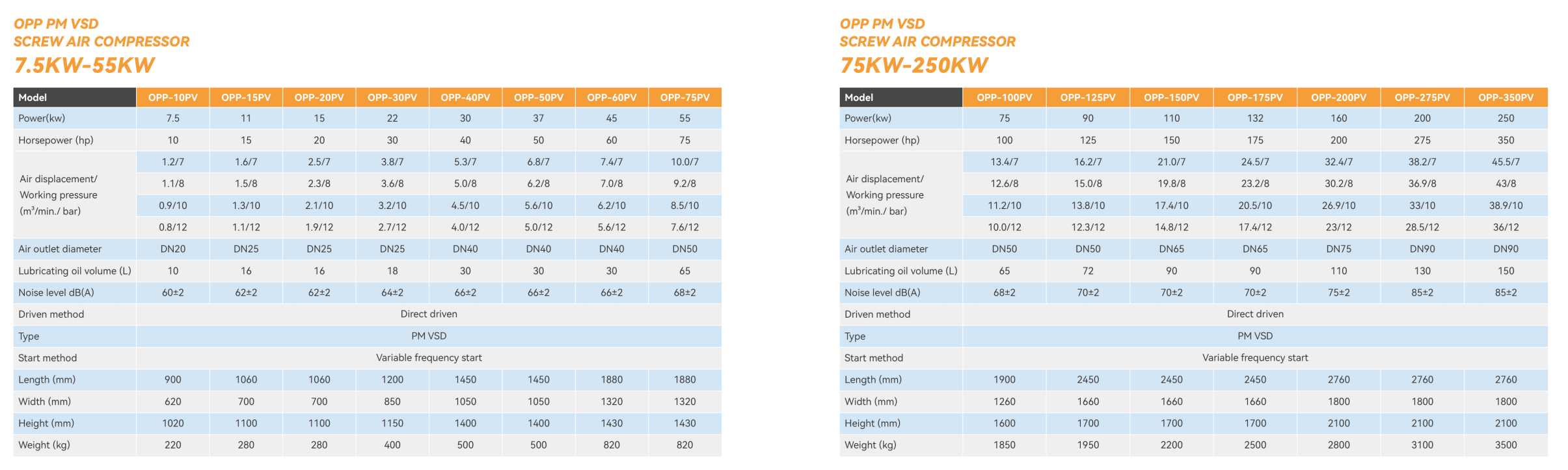

OPPAIR rotary screw air compressors are well known for their durability and efficient performance across a wide range of customer applications. With so many models to choose from and almost endless customization, OPPAIR has the compressor to fit your requirements. Whether you need direct, variable or fixed speed, low or high horsepower and CFM, OPPAIR has a comprehensive selection of models to choose from.

For decades now, the lubricated rotary screw compressor has been the most popular technology for the majority of industrial plant air applications from 5 to 350 HP and from 80-175 PSIG. There are many ways to review the different rotary screw offerings: comparing airend sizes, fixed vs. variable speed, enclosed vs. unenclosed and single vs. two-stage.

OPPAIR rotary screw air compressors are well known for their durability and efficient performance across a wide range of customer applications. With so many models to choose from and almost endless customization, OPPAIR has the compressor to fit your requirements. Whether you need direct or belt driven, variable or fixed speed, low or high kW and airflow, OPPAIR has a comprehensive selection of models to choose from.

For decades now, the lubricated rotary screw compressor has been the most popular technology for the majority of industrial plant air applications from 15kW to 250kW with air flows up to 50 m3/min.

Beyond the Compressor: Downstream Products & Aftermarket Support

A healthy compressed air system requires much more than just an air compressor. OPPAIR offers an extensive line of downstream equipment such as dryers, filters, chillers, piping and much more to complete your system. For information on how to connect a small screw air compressor to a cold dryer, air tank, and filter, please see the video below: https://youtu.be/9hg6Z_a4T0c?si=eGU76V_sy5URnlNv

Our dedicated distributor network provides OEM parts, service and support to keep your system running for years to come. (For details on post-maintenance, please refer to the following link https://www.oppaircompressor.com/news/how-to-maintain-screw-air-compressor/ )Using parts that are specifically designed for your equipment and only allowing authorized, certified technicians to provide you service, will not only protect your equipment investment, but also result in more efficient, reliable operation. #90KW 6/7/8/10Bar High Pressure Low Noise Two Stage Air Compressor Screw

Fixed vs. Variable Speed

Nearly every manufacturer offers customers both fixed and variable speed compressors in most size ranges. In general, variable speed (VS) compressors are applied when air demand varies significantly throughout a shift. This is because the VS compressors are more efficient (i.e. use less power (kW) per m3/min of air produced) than their fixed speed (FS) counterparts at part load (i.e. when the air system does not need all the air the compressor could make). Once you determine whether you need a FS or a VS compressor (or a combination), it is then most important to compare the efficiencies of the units involved. Be cautious in this area as many times VS compressors are recommended when they are not needed or do not project a reasonable ROI. Just because the VS compressor is the latest technology does not mean it is always the best compressor for the job. It is important to keep in mind that many times it is best to divide the air requirement between two or more compressors. In addition to providing some compressed air if one unit goes down, a multiple unit arrangement is often the most efficient design. And, this arrangement frequently combines fixed and variable speed units working together.

Single vs. Two-Stage

Two-stage lubricated rotaries compress air in two steps. Step or stage one takes atmospheric air and compresses it part way to the discharge pressure target. Step or stage two ingests the air at the inter-stage pressure and compresses it to the discharge pressure target. Compression in two stages improves efficiency, but adds cost and complexity given the additional rotors, iron and other componentry involved. Two-stage is generally offered in the higher kW sizes (above 75kW) because the improved efficiencies result in larger cost savings when air use is large. When comparing single stage versus two-stage, it is a relatively straightforward calculation to determine what the payback will be from the more efficient but more costly two-stage unit. Remember that the energy cost of operating a compressor is the largest expense over time, so evaluation of a two-stage machine is certainly worth a look.

Verified Performance

As a member of the Compressed Air and Gas Institute’s performance verification program, you can rest assured that the performance numbers that OPPAIR publishes are consistent with the actual performance of our machines. OPPAIR compressors, just as all lubricated rotary screw compressors 2.5 kW and above, are rigorously tested to ensure that our performance numbers are accurate, easy-to-understand and verified.

OPPAIR is looking for global agents, welcome to contact us for inquiries: WhatsApp: +86 14768192555

#Electric Rotary Screw air Compressor #Screw Air Compressor With Air Dryer #High Pressure Low Noise Two Stage Air Compressor Screw

Post time: Feb-27-2025