1. What is a four-in-one air compressor unit?

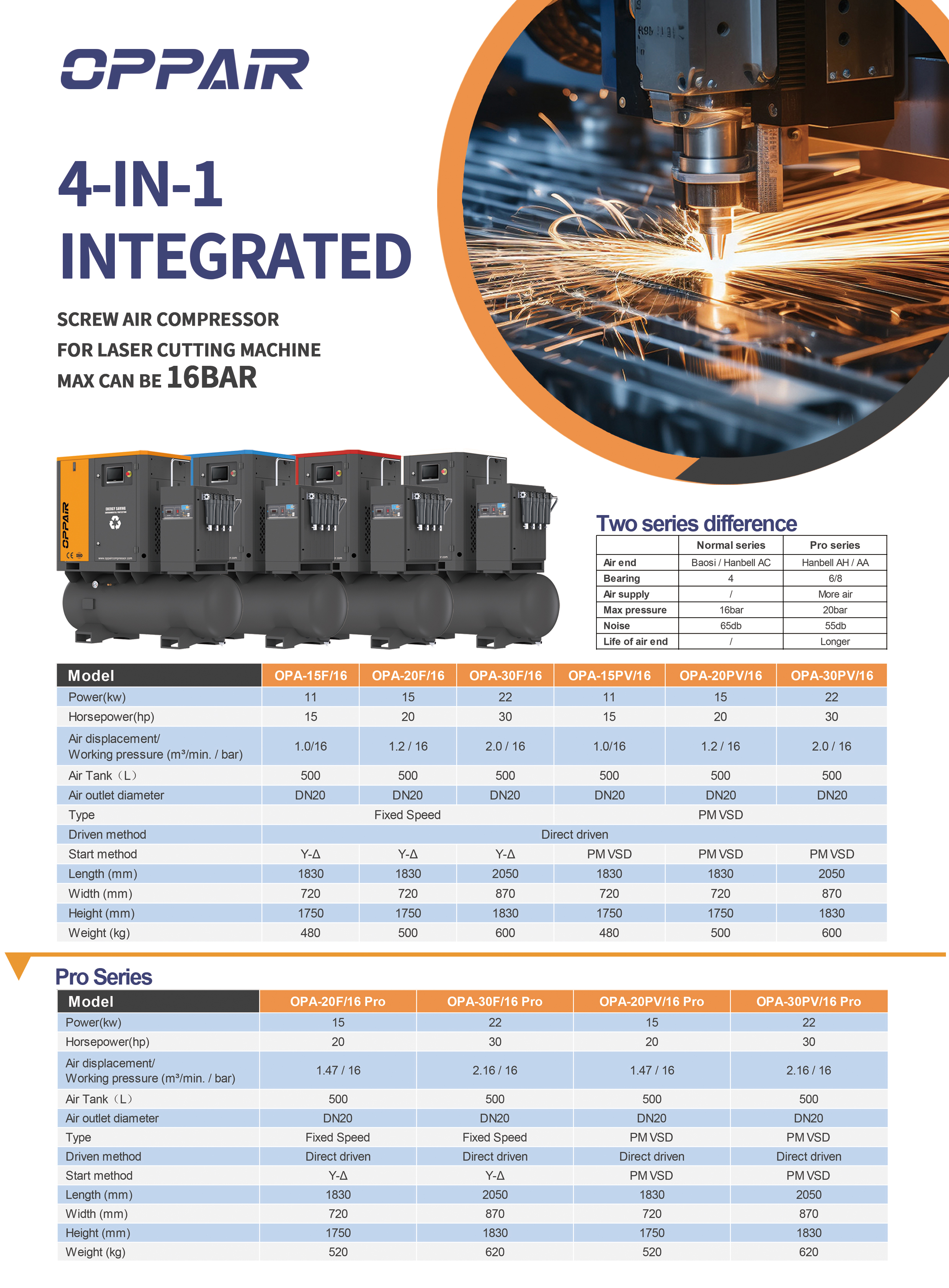

The all-in-one screw air compressor unit can integrate multiple air source equipment, such as rotary screw air compressors, air dryers, filters, and air tanks, to form a complete compressed air system, design different air source equipment in a platform-based manner, and build an efficient air source equipment combination, so as to achieve fast and efficient disposal of compressed air.

2. Application of OPPAIR 4-in-1 screw air compressor units

The OPPAIR four-in-one rotary air compressor unit is mostly used in occasions with high requirements for compressed air quality, such as food, medicine, electronics, aviation, automobiles and other fields. The equipment has low noise, light smell and saves maintenance costs, making it a more popular compressed air source equipment.

3. Core functional modules

Screw air compressor: responsible for compressing air and providing a stable air source.

Air dryer: removes moisture from compressed air to ensure dry output air.

Filter: filters impurities in the air to ensure air quality.

Air tank: stores compressed air to keep air pressure stable when demand fluctuates.

4. Advantages of the OPPAIR four-in-one screw air compressor unit

Save space:The all-in-one rotary air compressor unit integrates multiple air source equipment, which can save a lot of space during use compared to a single air source equipment.

Improve efficiency:The tank mounted all-in-one rotary screw air compressor unit realizes the platform design of air source equipment, which can realize the simultaneous operation of multiple air source equipment and improve the efficiency of air source use.

Reduce energy consumption:The 4-in-1 screw air compressor unit can realize full automatic control of the compressed air system and achieve more energy-saving purposes.

Reduce maintenance costs:Integrating multiple air source equipment together can reduce maintenance costs, and can reduce the downtime of the unit caused by replacement, maintenance and other reasons during maintenance, thereby reducing the operating cost of the unit.

5.Summary

The OPPAIR four-in-one screw air compressor unit is a device that integrates multiple air source equipment together to form an efficient and space-saving air source equipment combination, and has the advantages of energy saving and reduced maintenance costs. Its application field is very wide and it is a very popular air source equipment.

The four-in-one laser cutting machine has shown significant advantages and a wide range of applications in the application of laser cutting machines of brands such as Bystronic, Amada, Trumpf, MAZAK, Prima Power, Salvagnini, Baison Laser, etc. The following are the main application functions of the four-in-one laser cutting machine:

1. Welding function

The four-in-one laser cutting machine can complete the welding between metal materials at high speed and high quality, and is suitable for a variety of metals such as stainless steel, carbon steel, and aluminum alloy. The weld after welding is beautiful and has high strength, which is suitable for welding precision parts and complex structures.

2. Cleaning function

Using the high energy characteristics of the laser, the four-in-one laser cutting machine can perform non-contact cleaning on the metal surface, effectively removing impurities such as rust, paint, and oil. This method is more environmentally friendly, efficient, and does not damage the substrate than traditional chemical cleaning.

3. Cutting function

The four-in-one laser cutting machine can quickly and accurately cut metal sheets, whether it is straight lines, curves or complex patterns, and can achieve good edge cutting quality. This is suitable for cutting needs of various shapes and sizes.

4. Weld bead cleaning function

For the weld bead after welding, the four-in-one laser cutting machine can accurately remove oxides, residues, etc. around the weld to improve the cleanliness and beauty of the weld. This is crucial to improving the overall quality of the welded structure and the effect of subsequent processing (such as painting and testing).

The combination of these functions enables the four-in-one laser cutting machine to play an important role in many industries such as construction, machinery manufacturing, automobiles, and ships, and promotes the development of these industries towards efficient, intelligent, and high-end manufacturing.

OPPAIR is looking for global agents, welcome to contact us for inquiries: WhatsApp: +86 14768192555

Post time: Apr-11-2025