In the OPPAIR screw air compressor system, the air storage tank is an indispensable and important component. The air tank can not only effectively store and regulate compressed air, but also ensure the stable operation of the system and provide continuous and stable power support for various mechanical equipment. This article will analyze in detail all aspects of the compressed air system air storage tank, including its functions, safe use.

Functions of the air storage tank

1. Optimize air pressure: When the OPPAIR screw air compressor is running, a large amount of compression heat and gas pulsation will be generated, resulting in unstable exhaust pressure. The air storage tank can absorb gas pulsation and slow down the fluctuation amplitude of exhaust pressure, thereby stabilizing the air pressure. This can not only improve production efficiency, but also protect the rotary screw air compressor and downstream equipment.

2. Reduce air storage: The air storage tank can absorb the excess air generated by the screw air compressor and store it in the air tank. When gas is needed downstream, just take the gas from the gas tank without waiting for the rotary screw air compressors to produce gas. This can not only reduce energy consumption, but also improve production efficiency.

3. Buffering and pressure stabilization: The air tank plays a buffering role in the system, which can balance the supply and demand of the compressed air system, buffer peak consumption, and ensure that the system provides stable pressure.

Safe use of gas tanks

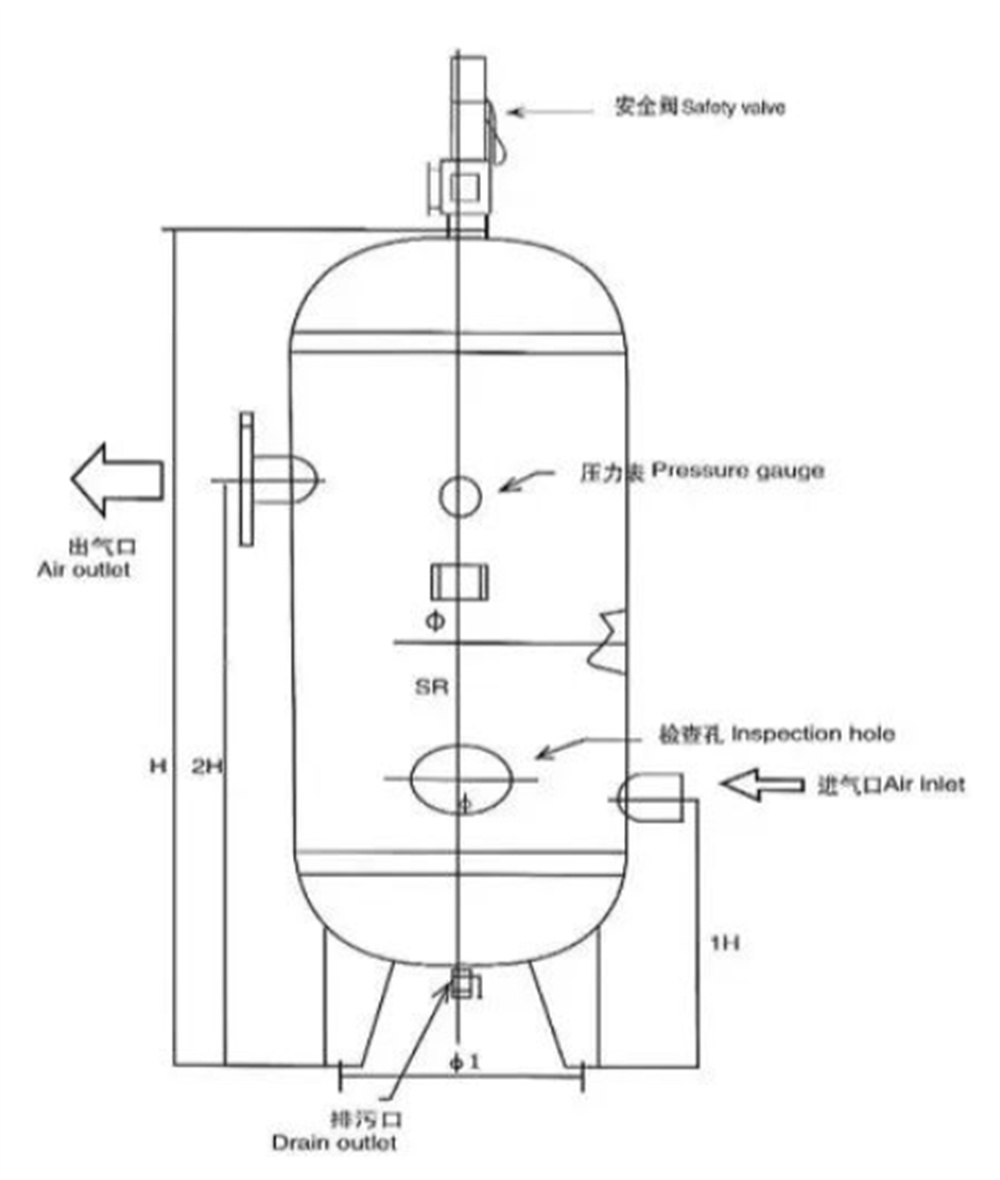

1. Selection and installation: Select the appropriate compresor de tornillo air tank capacity and pressure level according to the system needs and pressure requirements. At the same time, the air tank needs to be installed vertically on the horizontal ground and remain stable. The installation location should be away from fire sources and flammable materials to ensure safety.

2. Inspection and maintenance: Regularly inspect the air tank, including whether the container has cracks, corrosion and other damage, and whether the pressure gauge and safety valve are working properly. At the same time, regularly clean and drain condensed water to ensure that the air tank is clean and dry.

3. Discharge and pressure regulation: Regularly discharge the exhaust gas in the air tank according to actual needs. Be cautious when adjusting the pressure to avoid exceeding the operating pressure range of the pressure vessel.

4. Safety valve: The safety valve is an important safety device in the air tank, which can automatically release the pressure when the pressure exceeds the set range to prevent accidents. Therefore, it is necessary to regularly check and test the working status of the safety valve.

OPPAIR is looking for global agents, welcome to contact us for inquiries: WhatsApp: +86 14768192555

#Electric Rotary Screw air Compressor #Screw Air Compressor With Air Dryer #High Pressure Low Noise Two Stage Air Compressor Screw

Post time: Mar-12-2025