OPPAIR screw air compressor single-stage compression and two-stage compression principle:

Single-stage compression is One-time compression.

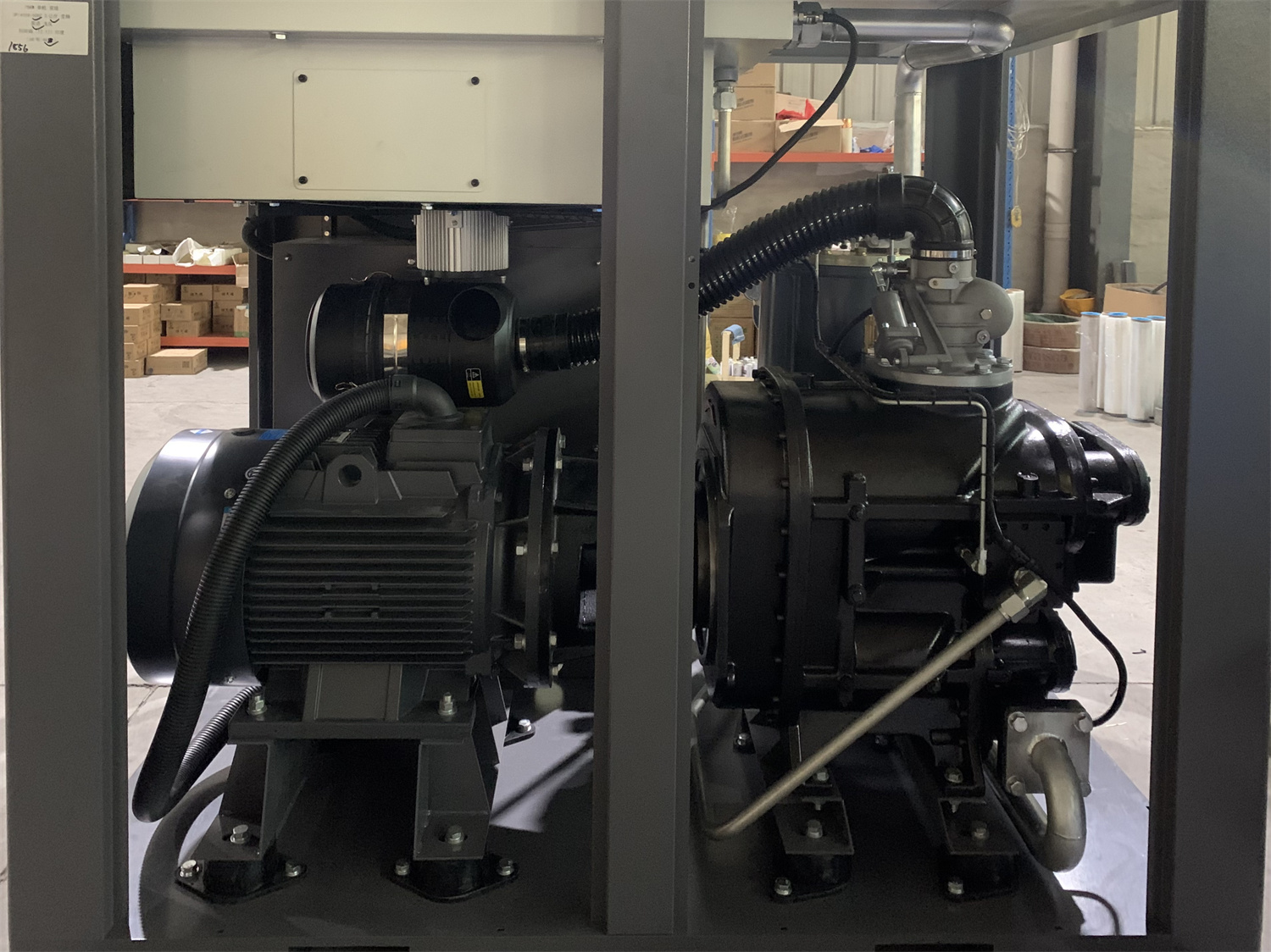

Two-stage compression is the air compressed in the first stage enters the second stage of boosting and two-stage compression. The single-stage compression rotor and the two-stage compression rotor are combined in one casing and directly driven by helical gears. Natural air enters the first stage of compression through the air filter, mixes with a small amount of lubricating oil in the compression yard, and compresses the mixed air to the inter-stage pressure. The compressed air enters the cooling channel and contacts with a large amount of oil mist, which greatly reduces the temperature. The compressed air after dehumidification enters the second stage rotor for secondary compression and is compressed to the final exhaust pressure. Finally, it is discharged from the compressor through the exhaust flange to complete the entire compression process.

https://www.oppaircompressor.com/2-stage-screw-compressor-products/

Advantages of OPPAIR two-stage compression screw air compressor:

1. Energy saving.

OPPAIR two-stage compression uses intercooling to make the air before the second compression close to the air just compressed in the air compressor. We all know that the higher the temperature of the air, the more energy it consumes to compress it than the air at normal temperature. The isothermal compression principle is used, and a large amount of heat waste will not be generated, so the energy utilization efficiency is relatively high.

2. Higher pressure.

OPPAIR two-stage compression can compress the air to a higher pressure, usually around 15-40 bar, based on single-stage compression. Therefore, the pressure that two-stage compression can achieve is much higher than that of single-stage compression.

3. Higher air production.

OPPAIR two-stage compression has a higher main unit volume ratio, so the air production is also higher, which is equivalent to an OPPAIR 90KW two-stage compressor that can produce the air of a 110KW single-stage compressor at the same energy consumption.

In short, the difference between OPPAIR screw air compressor two-stage compression and single-stage compression lies in the pressure of compressed air. The main reason why air compressors need two-stage compression is that high-pressure air is needed to complete specific process operations in certain industrial fields. In addition, OPPAIR two-stage compression can also improve the efficiency and energy consumption of air compressors, reduce the content of moisture and grease, and improve the quality and purity of air.

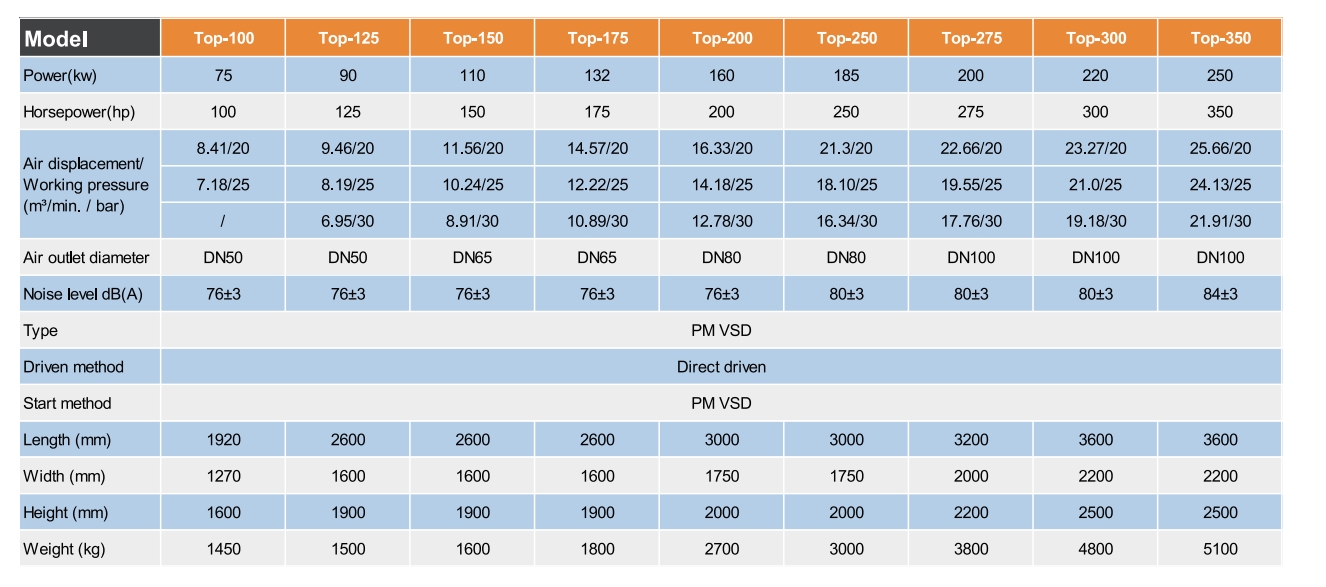

Attached is the product brochure of OPPAIR low-pressure and high-pressure two-stage compression.

#Direct Drive Screw Air Compressor #two stage PM VSD compressor #Two-Stage Compression Frequency Conversion Screw Air Compressor #compressor with CE certificate #screw air compressor with oil lubricated

Post time: Mar-03-2025