Operation Instructions

-

Advantages of OPPAIR two-stage screw air compressor

Advantages of OPPAIR two-stage compression of screw air compressor? Why is OPPAIR two-stage rotary screw air compressor the first choice for screw air compressor? Let’s talk about OPPAIR two-stage screw air compressor todays. 1. Two-stage screw air compressor compresses air through two syn...Read more -

How to Choose a Laser Cutting Screw Air Compressor

The following aspects need to be considered: The performance parameters of the screw air compressors: including power, pressure, air flow, etc. These parameters need to be determined according to the specific laser cutting equipment and process requirements. The stability and reliability of the ...Read more -

OPPAIR Four-in-One Screw Air Compressor Introduction and Application in laser cutting

1. What is a four-in-one air compressor unit? The all-in-one screw air compressor unit can integrate multiple air source equipment, such as rotary screw air compressors, air dryers, filters, and air tanks, to form a complete compressed air system, design different air source equipment in a platfo...Read more -

Advantages of 4-in-1 screw air compressor in laser cutting

The old piston machine consumes a lot of power, makes a lot of noise, and has high enterprise costs, which also seriously affects the physical and mental health of on-site operators. Customers hope that the air compressor can meet multiple demands such as energy saving, intelligent control, stabl...Read more -

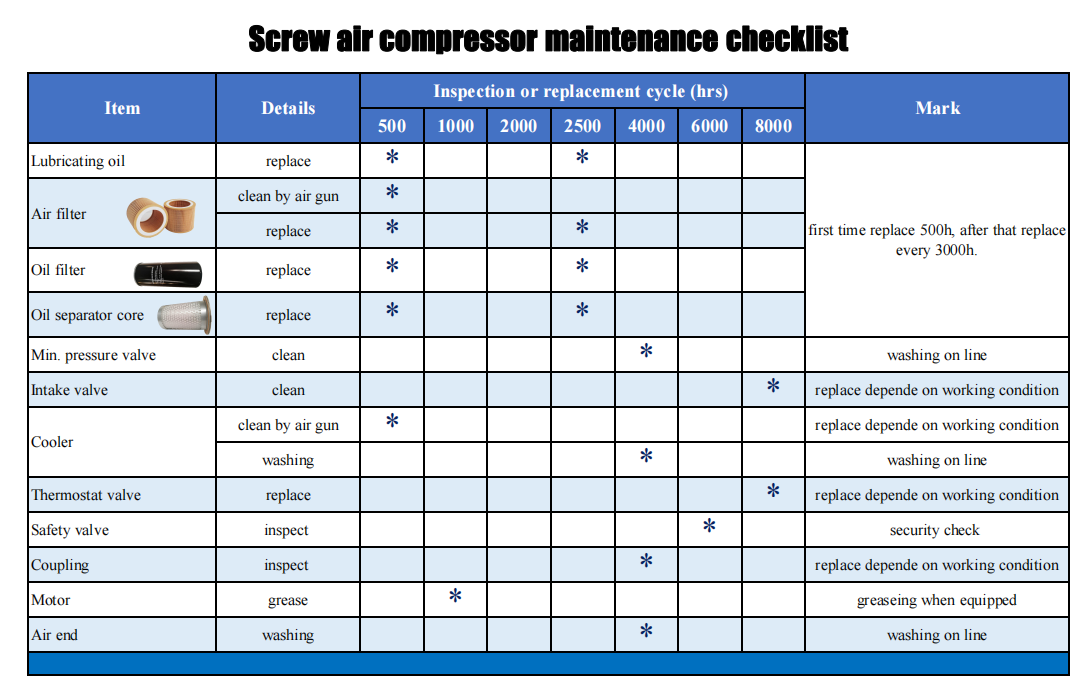

How to maintain screw air compressor?

In order to avoid premature wear of the screw compressor and blockage of the fine filter element in the oil-air separator, the filter element usually needs to be cleaned or replaced. First time 500 hours, then every 2500 hours maintenance once; In dusty areas, the replac...Read more -

Screw air compressor installation tutorial and installation precautions, as well as maintenance precautions

Most customers who buy screw air compressors often don’t pay much attention to the installation of screw air compressors. However, screw air compressors are very important during use. But once there is a small problem with the screw air compressor, it will affect the pr...Read more -

Lubricated Rotary Screw Air Compressor Solutions

OPPAIR Rotary screw compressors are ideal for so many industries and applications. Unlike reciprocating compressors, rotary screw compressors are designed for continuous compressed air use and produce a consistent flow of air. Commercial and industrial businesses generally choose rotary compresso...Read more -

How to replace the filter of OPPAIR screw air compressor

The application range of air compressors is still very wide, and many industries are using OPPAIR air compressors. There are many types of air compressors. Let's take a look at the replacement method of the OPPAIR air compressor filter. ...Read more