Customer service staff online 7/24

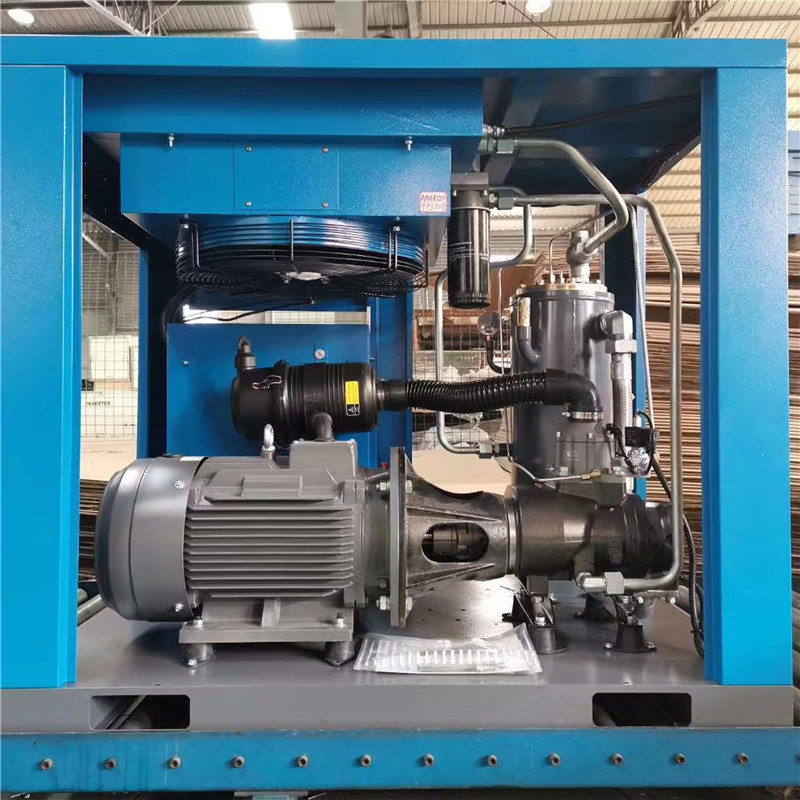

Professional Design Industrial Rotary Screw Air Compressor - Four in One Screw Air Compressor Compressed Air with dryer – OPPAIR

Professional Design Industrial Rotary Screw Air Compressor - Four in One Screw Air Compressor Compressed Air with dryer – OPPAIR Detail:

Product Parameters

Normal Pressure

| Model | OPA-10F | OPA-15F | OPA-20F | OPA-30F | OPA-10PV | OPA-15PV | OPA-20PV | OPA-30PV | |

| Power(kw) | 7.5 | 11 | 15 | 22 | 7.5 | 11 | 15 | 22 | |

| Horsepower(hp) | 10 | 15 | 20 | 30 | 10 | 15 | 20 | 30 | |

| Air displacement/ Working pressure (m³/min. / Bar) |

1.2/7 | 1.6/7 | 2.5/7 | 3.8/7 | 1.2/7 | 1.6/7 | 2.5/7 | 3.8/7 | |

| 1.1/8 | 1.5/8 | 2.3/8 | 3.6/8 | 1.1/8 | 1.5/8 | 2.3/8 | 3.6/8 | ||

| 0.9/10 | 1.3/10 | 2.1/10 | 3.2/10 | 0.9/10 | 1.3/10 | 2.1/10 | 3.2/10 | ||

| 0.8/12 | 1.1/12 | 1.9/12 | 2.7/12 | 0.8/12 | 1.1/12 | 1.9/12 | 2.7/12 | ||

| Air Tank(L) | 380 | 380/500 | 380/500 | 500 | 380 | 380/500 | 380/500 | 500 | |

| Type | Fixed Speed | Fixed Speed | Fixed Speed | Fixed Speed | PM VSD | PM VSD | PM VSD | PM VSD | |

| Air out let diameter |

DN20 | DN40 | DN40 | DN40 | DN20 | DN40 | DN40 | DN40 | |

| Lubricating oil volume (L) | 10 | 16 | 16 | 18 | 10 | 16 | 16 | 18 | |

| Noise level dB(A) | 60±2 | 62±2 | 62±2 | 68±2 | 60±2 | 62±2 | 62±2 | 68±2 | |

| Driven method | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | |

| Start method | Υ-Δ | Υ-Δ | Υ-Δ | Υ-Δ | PM VSD | PM VSD | PM VSD | PM VSD | |

| Length (mm) | 1750 | 1820 | 1820 | 1850 | 1750 | 1820 | 1820 | 1850 | |

| Width (mm) | 750 | 760 | 760 | 870 | 750 | 760 | 760 | 870 | |

| Height (mm) | 1550 | 1800 | 1800 | 1850 | 1550 | 1800 | 1800 | 1850 | |

| Weight (kg) | 380 | 420 | 420 | 530 | 380 | 420 | 420 | 530 | |

High Pressure

| Model | OPA-15F/16 | OPA-20F/16 | OPA-30F/16 | OPA-15PV/16 | OPA-20PV/16 | OPA-30PV/16 | |

| Power(kw) | 11 | 15 | 22 | 11 | 15 | 22 | |

| Horsepower(hp) | 15 | 20 | 30 | 15 | 20 | 30 | |

| Air displacement/ Working pressure (m³/min. / Bar) |

1.0/16 | 1.2 / 16 | 2.0 / 16 | 1.0/16 | 1.2 / 16 | 2.0 / 16 | |

| Air Tank(L) | 380/500 | 380/500 | 500 | 380/500 | 380/500 | 500 | |

| Air Out let diameter | DN20 | DN20 | DN20 | DN20 | DN20 | DN20 | |

| Type | Fixed Speed | Fixed Speed | Fixed Speed | PM VSD | PM VSD | PM VSD | |

| Driven method | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | Direct driven | |

| Start method | Υ-Δ | Υ-Δ | Υ-Δ | PM VSD | PM VSD | PM VSD | |

| Length (mm) | 1820 | 1820 | 1850 | 1820 | 1820 | 1850 | |

| Width (mm) | 760 | 760 | 870 | 760 | 760 | 870 | |

| Height (mm) | 1800 | 1800 | 1850 | 1800 | 1800 | 1850 | |

| Weight (kg) | 420 | 420 | 530 | 420 | 420 | 530 | |

Product description

MOTOR

1. The motor uses high-performance motors of well-known brands. Permanent magnet synchronous motors (PM motors) use high-performance NdFeB permanentmagnets which will not lose magnetism under 200. and its service life reaches as long as 15 years.

2. The stator coil uses the frequency converter special halo proof enameled wire, theinsulation is outstanding and the service life is longer.

3. The motor has the function of temperature protection. It also has a wide range of motor speed regulation, high precision and wide range of volume regulation. The reliability is significantly improved with small size, low noise and large excess current.

4. Protection grade IP55, insulation grade F, efectively protects the motor and increases the serice life of the motor, the eficiency is 5% 7% higher than similar products.

INTAKE VALVE

1. Intake valve is the core component to control the air intake of the air compressor.

2. Adopting the world famous brand air intake valve, it can automatically adjust theair volume by 0-100% according to the requirement of the system air quantity. It promises small pressure loss, stable action and long life consequently reduced operating costs.

HEAT EXHANGER

1. The heat exchanger uses high-quality raw materials and a unique intemal channel design, which increases the heat exchange area and can effectively dissipate heat for the air compressor.

2. The inner wall of the heat exchanger is treated with corrosion protection to increase the service life of the heat exchanger and increase the heat transfer effect.

3. The radiator has passed the strict factory test, and the quality is reliable, which efetively prevents the high temperature of the air compressor and increases the service life of the machine.

Product details

Factory Tour

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for Professional Design Industrial Rotary Screw Air Compressor - Four in One Screw Air Compressor Compressed Air with dryer – OPPAIR , The product will supply to all over the world, such as: Curacao, Bangladesh, Italy, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We will not live up to the historic opportunity of the times.

Shandong OPPAIR Machinery Manufacturing Co.,Ld base in Linyi Shandong, anAAA-level enterprise with high-quality service and integrity in China.

OPPAIR as one of the world’s largest air compressor system suppliers, currently developing the following products: Fixed-speed Air Compressors, Permanent Magnet VariableFrequency Air Compressors, Permanent Magnet Variable Frequency Two-stage Air Compressors, 4-IN-1 Air Compressors (lntegrated Air Compressor for Laser Cutting Machine)Supercharger, Freeze Air Dryer, Adsorption Dryer, Air Storage Tank and related accessories.

OPPAIR air compressor products are deeply trusted by customers.

The company has always operated in good faith in the direction of customer service first, integrity first, and quality first. We hope you will join the OPPAIR family and welcome you.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

Top