Customer service staff online 7/24

Super Purchasing For Industrial Rotary Screw Air Compressor - 40hp Frequency conversion screw air compressor – OPPAIR

Super Purchasing For Industrial Rotary Screw Air Compressor - 40hp Frequency conversion screw air compressor – OPPAIR Detail:

Fixed Speed Screw Air Compressor

| Model | OPP-10F | OPP-15F | OPP-20F | OPP-30F | OPP-40F | OPP-50F | OPP-60F | OPP-75F | |

| Power (kw) | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | |

| Horsepower (hp) | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 75 | |

| Air displacement/ Working pressure (M³/Min. / bar) |

1.2 / 7 | 1.6 / 7 | 2.5 / 7 | 3.8 / 7 | 5.3 / 7 | 6.8 / 7 | 7.4 / 7 | 10.0 / 7 | |

| 1.1 / 8 | 1.5/8 | 2.3/8 | 3.6 / 8 | 5.0 / 8 | 6.2 / 8 | 7.0 / 8 | 9.2 / 8 | ||

| 0.9 / 10 | 1.3 / 10 | 2.1 / 10 | 3.2 / 10 | 4.5 / 10 | 5.6 / 10 | 6.2 / 10 | 8.5 / 10 | ||

| 0.8 / 12 | 1.1 / 12 | 1.9 / 12 | 2.7 / 12 | 4.0 / 12 | 5.0 / 12 | 5.6 / 12 | 7.6 / 12 | ||

| Air out let diameter |

DN20 | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | DN50 | |

| Lubricating oil volume (L) | 10 | 16 | 16 | 18 | 30 | 30 | 30 | 65 | |

| Noise level dB(A) | 60±2 | 62±2 | 62±2 | 64±2 | 66±2 | 66±2 | 66±2 | 68±2 | |

| Driven method | Direct driven | ||||||||

| Type | Fixed Speed | ||||||||

| Start method | Υ-Δ | ||||||||

| Length (mm) | 950 | 1150 | 1150 | 1350 | 1500 | 1500 | 1500 | 1900 | |

| Width (mm) | 670 | 820 | 820 | 920 | 1020 | 1020 | 1020 | 1260 | |

| Height (mm) | 1030 | 1130 | 1130 | 1230 | 1310 | 1310 | 1310 | 1600 | |

| Weight (kg) | 250 | 400 | 400 | 550 | 700 | 750 | 800 | 1750 | |

| Model | OPP-100F | OPP-125F | OPP-150F | OPP-175F | OPP-200F | OPP-275F | OPP-350F | |

| Power (kw) | 75.0 | 90 | 110 | 132 | 160 | 200 | 250 | |

| Horsepower (hp) | 100 | 125 | 150 | 175 | 200 | 275 | 350 | |

| Air displacement/ Working pressure (M³/Min. / bar) |

13.4 / 7 | 16.2 / 7 | 21.0 / 7 | 24.5 / 7 | 32.4 / 7 | 38.2 / 7 | 45.5 / 7 | |

| 12.6 / 8 | 15.0 / 8 | 19.8 / 8 | 23.2 / 8 | 30.2 / 8 | 36.9 / 8 | 43 / 8 | ||

| 11.2 / 10 | 13.8 / 10 | 17.4 / 10 | 20.5 / 10 | 26.9 / 10 | 33/ / 10 | 38.9 / 10 | ||

| 10.0 / 12 | 12.3 / 12 | 14.8 / 12 | 17.4 / 12 | 23 / 12 | 28.5 / 12 | 36 / 12 | ||

| Air out let diameter |

DN50 | DN50 | DN65 | DN65 | DN75 | DN90 | DN90 | |

| Lubricating oil volume (L) | 65 | 72 | 90 | 90 | 110 | 130 | 150 | |

| Noise level dB(A) | 68±2 | 70±2 | 70±2 | 70±2 | 75±2 | 85±2 | 85±2 | |

| Driven method | Direct driven | |||||||

| Type | Fixed Speed | |||||||

| Start method | Υ-Δ | |||||||

| Length (mm) | 1900 | 2450 | 2450 | 2450 | 2760 | 2760 | 2760 | |

| Width (mm) | 1260 | 1660 | 1660 | 1660 | 1800 | 1800 | 1800 | |

| Height (mm) | 1600 | 1700 | 1700 | 1700 | 2100 | 2100 | 2100 | |

| Weight (kg) | 1850 | 1950 | 2200 | 2500 | 2800 | 3100 | 3500 | |

Permanent Magnet Frequency Conversion Series

| Model | OPP-10PV | OPP-15PV | OPP-20PV | OPP-30PV | OPP-40PV | OPP-50PV | OPP-60PV | OPP-75PV | |

| Power (kw) | 7.5 | 11 | 15 | 22 | 30 | 37 | 45 | 55 | |

| Horsepower (hp) | 10 | 15 | 20 | 30 | 40 | 50 | 60 | 75 | |

| Air displacement/ Working pressure (M³/Min. / bar) |

1.2 / 7 | 1.6 / 7 | 2.5 / 7 | 3.8 / 7 | 5.3 / 7 | 6.8 / 7 | 7.4 / 7 | 10.0 / 7 | |

| 1.1 / 8 | 1.5/8 | 2.3/8 | 3.6 / 8 | 5.0 / 8 | 6.2 / 8 | 7.0 / 8 | 9.2 / 8 | ||

| 0.9 / 10 | 1.3 / 10 | 2.1 / 10 | 3.2 / 10 | 4.5 / 10 | 5.6 / 10 | 6.2 / 10 | 8.5 / 10 | ||

| 0.8 / 12 | 1.1 / 12 | 1.9 / 12 | 2.7 / 12 | 4.0 / 12 | 5.0 / 12 | 5.6 / 12 | 7.6 / 12 | ||

| Air out let diameter |

DN20 | DN25 | DN25 | DN25 | DN40 | DN40 | DN40 | DN50 | |

| Lubricating oil volume (L) | 10 | 16 | 16 | 18 | 30 | 30 | 30 | 65 | |

| Noise level dB(A) | 60±2 | 62±2 | 62±2 | 64±2 | 66±2 | 66±2 | 66±2 | 68±2 | |

| Driven method | Direct driven | ||||||||

| Type | PM VSD | ||||||||

| Start method | Variable frequency start | ||||||||

| Length (mm) | 950 | 1150 | 1150 | 1350 | 1500 | 1500 | 1500 | 1900 | |

| Width (mm) | 670 | 820 | 820 | 920 | 1020 | 1020 | 1020 | 1260 | |

| Height (mm) | 1030 | 1130 | 1130 | 1230 | 1310 | 1310 | 1310 | 1600 | |

| Weight (kg) | 250 | 400 | 400 | 550 | 700 | 750 | 800 | 1750 | |

| Model | OPP-100PV | OPP-125F | OPP-150PV | OPP-175PV | OPP-200PV | OPP-275PV | OPP-350PV | |

| Power (kw) | 75.0 | 90 | 110 | 132 | 160 | 200 | 250 | |

| Horsepower (hp) | 100 | 125 | 150 | 175 | 200 | 275 | 350 | |

| Air displacement/ Working pressure (M³/Min. / bar) |

13.4 / 7 | 16.2 / 7 | 21.0 / 7 | 24.5 / 7 | 32.4 / 7 | 38.2 / 7 | 45.5 / 7 | |

| 12.6 / 8 | 15.0 / 8 | 19.8 / 8 | 23.2 / 8 | 30.2 / 8 | 36.9 / 8 | 43 / 8 | ||

| 11.2 / 10 | 13.8 / 10 | 17.4 / 10 | 20.5 / 10 | 26.9 / 10 | 33/ / 10 | 38.9 / 10 | ||

| 10.0 / 12 | 12.3 / 12 | 14.8 / 12 | 17.4 / 12 | 23 / 12 | 28.5 / 12 | 36 / 12 | ||

| Air out let diameter |

DN50 | DN50 | DN65 | DN65 | DN75 | DN90 | DN90 | |

| Lubricating oil volume (L) | 65 | 72 | 90 | 90 | 110 | 130 | 150 | |

| Noise level dB(A) | 68±2 | 70±2 | 70±2 | 70±2 | 75±2 | 85±2 | 85±2 | |

| Driven method | Direct driven | |||||||

| Type | PM VSD | |||||||

| Start method | Variable frequency start | |||||||

| Length (mm) | 1900 | 2450 | 2450 | 2450 | 2760 | 2760 | 2760 | |

| Width (mm) | 1260 | 1660 | 1660 | 1660 | 1800 | 1800 | 1800 | |

| Height (mm) | 1600 | 1700 | 1700 | 1700 | 2100 | 2100 | 2100 | |

| Weight (kg) | 1850 | 1950 | 2200 | 2500 | 2800 | 3100 | 3500 | |

Product description

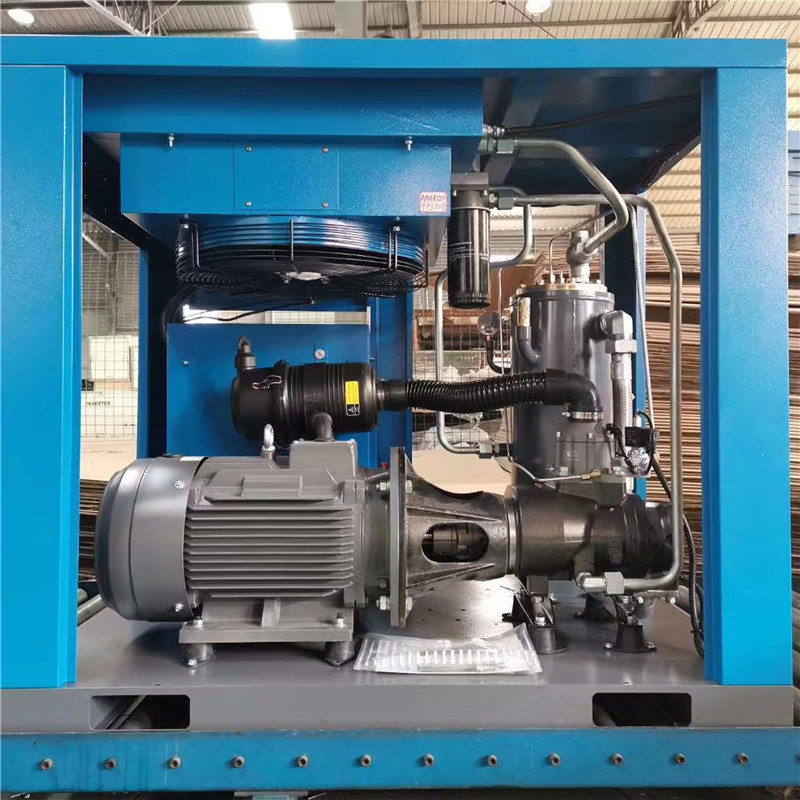

FAN

1. The fan uses a large fan design to effectively enhance the fan’s heat dissipation effect.The motor adopts a special intermnal design to adapt to harsh working conditions.

2. The fan motor adopts specal winding and high protection grade design to adapt to harsh working conditions.

3. The fan is controlld by the controller to realie the automatic start and stop function, which efctively maintains the normal working temperature of the air compressor lubricant.

INTAKE VALVE

1. Intake valve is the core component to control the air intake of the air compressor.

2. Adopting the world famous brand air intake valve, it can automatically adjust theair volume by 0-100% according to the requirement of the system air quantity. It promises small pressure loss, stable action and long life consequently reduced operating costs.

HEAT EXHANGER

1. The heat exchanger uses high-quality raw materials and a unique intemal channel design, which increases the heat exchange area and can effectively dissipate heat for the air compressor.

2. The inner wall of the heat exchanger is treated with corrosion protection to increase the service life of the heat exchanger and increase the heat transfer effect.

3. The radiator has passed the strict factory test, and the quality is reliable, which efetively prevents the high temperature of the air compressor and increases the service life of the machine.

Product features

1. The screw air compressor has the advantages of high stability, high efficiency, low vibration and low noise.

2. The yin and yang rotors and the coordination between the rotor and the casing are set, so that the backflow leakage of the gas is less, and there is no residual clearance volume, so the efficiency is high.

3. The injected lubricating oil has the functions of sealing, cooling, noise reduction and lubrication

4. Compared with piston machine, it has less wearing parts and lower failure rate.

5. The screw compression working curve is smooth, with less vibration and low noise compared with the piston machine.

6. The cooling method is generally divided into: water cooling and air cooling.

7. Heat dissipation system: plate-fin structure and high-quality materials are used to ensure that the cooler can withstand pressure, have high heat dissipation efficiency and good corrosion resistance.

8. Air filter: heavy-duty, multi-stage air inlet filter, dust removal accuracy 1um (98% is filtered out), large working surface, relatively long service life.

9. Oil/gas separator: The new generation of separator adopts a new filter material, with higher efficiency, and the air oil content is less than 2ppm.

10. Intelligent controller: All operations and related data of the air compressor are displayed on the control panel, which can be controlled between your fingers, easy, convenient and accurate.

Air Compressor Equipment – Screw air compressors drive the compression components at the optimum speed for the application through an efficient drive system. Completely maintenance-free during normal operation.

Product Details

Factory Tour

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers", hopes to become the top cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Super Purchasing For Industrial Rotary Screw Air Compressor - 40hp Frequency conversion screw air compressor – OPPAIR , The product will supply to all over the world, such as: Ukraine, Denver, Anguilla, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

Shandong OPPAIR Machinery Manufacturing Co.,Ld base in Linyi Shandong, anAAA-level enterprise with high-quality service and integrity in China.

OPPAIR as one of the world’s largest air compressor system suppliers, currently developing the following products: Fixed-speed Air Compressors, Permanent Magnet VariableFrequency Air Compressors, Permanent Magnet Variable Frequency Two-stage Air Compressors, 4-IN-1 Air Compressors (lntegrated Air Compressor for Laser Cutting Machine)Supercharger, Freeze Air Dryer, Adsorption Dryer, Air Storage Tank and related accessories.

OPPAIR air compressor products are deeply trusted by customers.

The company has always operated in good faith in the direction of customer service first, integrity first, and quality first. We hope you will join the OPPAIR family and welcome you.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

Top